Compressor Fleet Management

There’s Too Much on the (Pipe)Line to Make Assumptions

Unlock your compressor fleet’s full potential with universal connectivity, data-driven insights, digital twin simulation technology, edge computing, and the expertise of a dedicated team specializing in oil and gas operations.

Welcome to the Future of Oilfield Efficiency

The next era of oilfield management is built on the foundation of accuracy, efficiency, and operator confidence. As an oilfield operator, you’re at the forefront of your organization’s evolution.

Evolving Compression Fleets For A New Era

Detechtion transforms your vision for optimized compressor performance into actionable results, solving operational limitations commonly faced in the oil and gas industry.

In a Perfect World:

- Your monitoring solution provides visibility into your compression fleet and delivers actionable insights to optimize equipment performance.

- Using these insights, you can focus on maximizing returns and addressing the most significant opportunities within your fleet.

- Your systems adapt seamlessly to changing regulatory environments.

In Reality:

Disconnected systems, reactive repairs, and limited resources make optimization difficult and jeopardize compressor integrity.

It’s Time to Bridge the Gap

Detechtion bridges the gap by turning your optimization goals into real-world results with solutions designed for oilfield challenges.

What is Compressor Fleet Management?

Workflows are the foundation of compressor fleet success in the oil and gas sector, impacting operational performance and profitability.

Traditional Approach:

Manually collecting data on-site hinders proactive maintenance, future-oriented decision-making, and the ability to maximize your fleet's potential.

Detechtion Compressor Fleet Management:

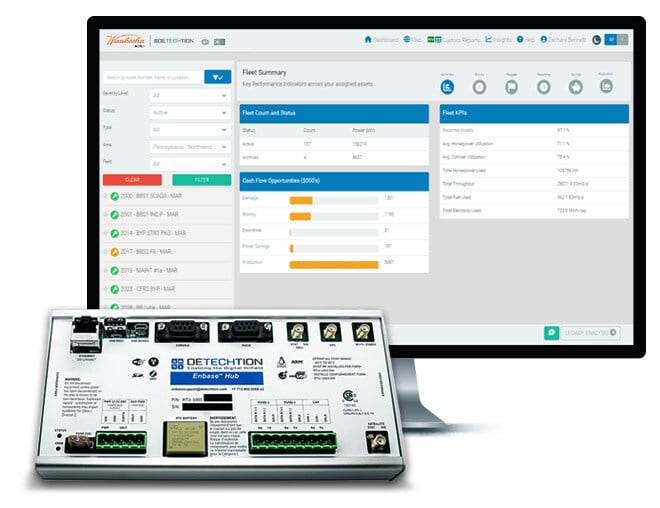

Detechtion’s universal connectivity provides granular data on individual compressor efficiency and holistic insights into fleet performance, empowering proactive decision-making and optimization.

Why Compressor Fleet Management Matters

In oil and gas operations, turning a profit and maximizing utilization depend on deep visibility into compressor performance at every level.

Traditional Approach:

- Disconnected systems and fragmented data streams complicate optimization, leading to missed opportunities.

- Unplanned shutdowns stretch operators thin and shift focus away from strategic objectives.

Detechtion Compressor Fleet Management:

-

360° Fleet Visibility: Proactively resolve issues and minimize downtime.

-

Remote Optimization: Increase fleet productivity and reliability with real-time set point adjustments.

-

Focus on Strategy: Free up operator time to concentrate on long-term goals.

Data Makes All The Difference

Remotely fine-tune equipment based on operating conditions to maximize production while minimizing energy usage.

Controlling assets remotely helps you streamline callout response and prioritize your maintenance team’s time for what matters most.

Automate asset modeling to enable the widest allowable operating range and repair failing components before they cause shutdowns.

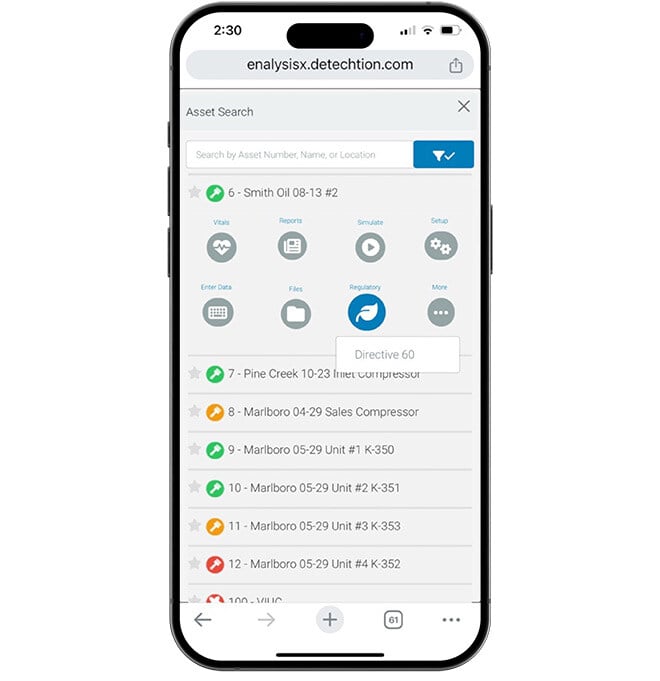

Complete regulatory reports, implement sustainability initiatives, minimize environmental impact, and ensure compliance without lifting a finger.

Remotely fine-tune equipment based on operating conditions to maximize production while minimizing energy usage.

Controlling assets remotely helps you streamline callout response and prioritize your maintenance team’s time for what matters most.

Automate asset modeling to enable the widest allowable operating range and repair failing components before they cause shutdowns.

Complete regulatory reports, implement sustainability initiatives, minimize environmental impact, and ensure compliance without lifting a finger.

How Compressor Fleet Management Happens

Effective systems are essential for compressor fleet success, especially in oilfield operations.

Traditional Approach:

-

Time-consuming on-site data collection limits efficiency.

-

Reactive shutdown responses increase costs and hinder productivity.

Detechtion Compressor Fleet Management:

Real-time data integration simplifies operations, reduces admin tasks, and ensures accurate data for decision-making.

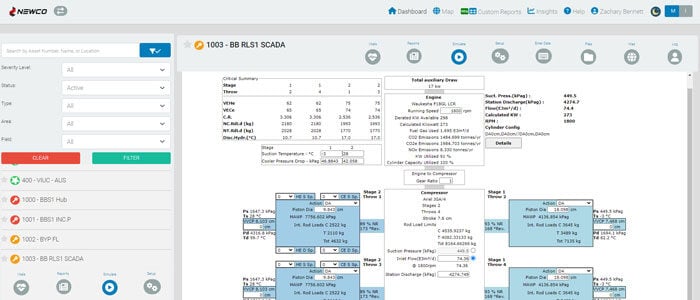

Monitoring

Detechtion’s monitoring solutions provide fleetwide visibility to track compression packages, manage callouts, and optimize runtime for oil and gas operations.

Empowering 360° Fleet Transparency

- Structured Callout Management: Respond quickly to minimize downtime and losses.

- Universal Connectivity: Seamless data collection for proactive decision-making.

- Future-Proof Repairs: Use downtime data for root cause analysis and proactive maintenance.

- Holistic Fleet Insights: Historical data drives productivity and optimization.

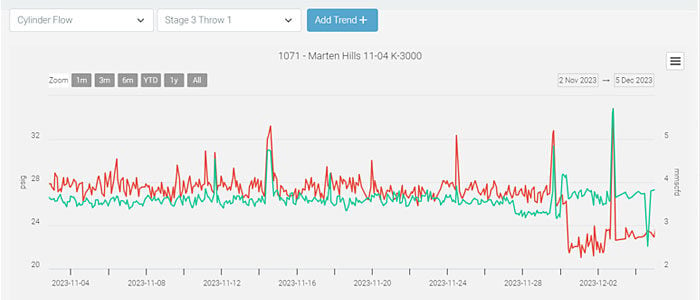

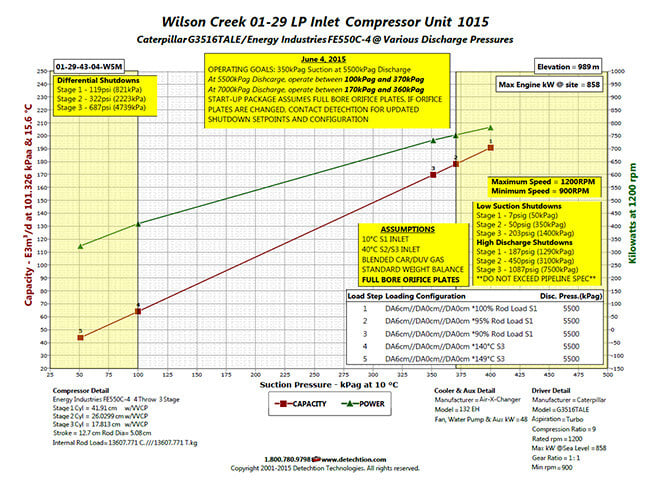

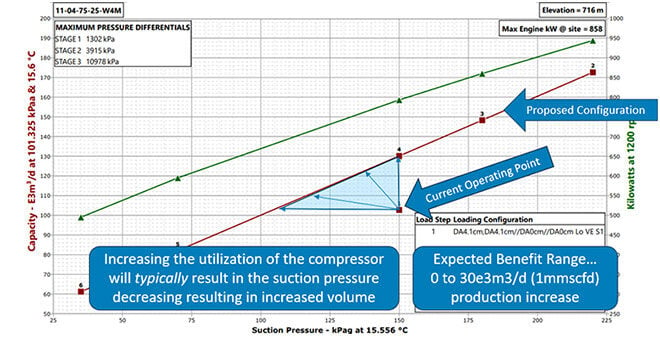

Optimization

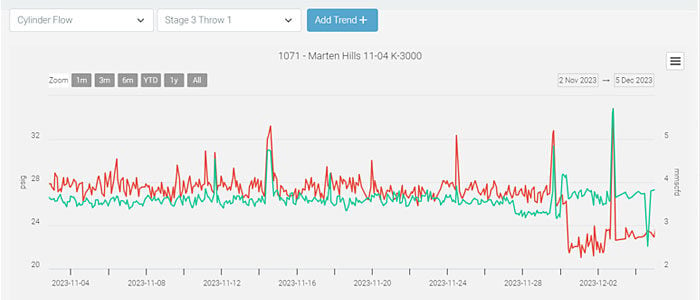

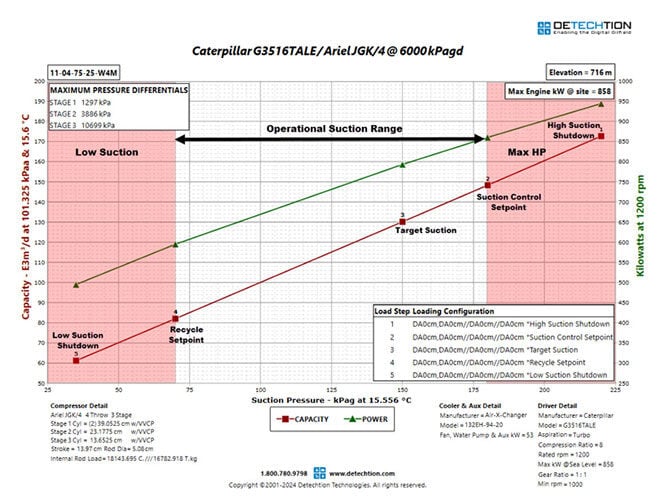

Our software enhances efficiency by optimizing compressor utilization, reducing shutdowns, and minimizing energy use in oilfield operations.

How Detechtion Reimagines Operational Efficiency:

- Maximize Output: Identify field-specific opportunities and scale solutions fleetwide.

- Predictive Technology: Use digital twin simulations for optimized decision-making.

- Asset Modeling: Allow broader operating ranges to reduce downtime and costs.

- Reduce Energy Use: Optimize power consumption to cut emissions and improve sustainability.

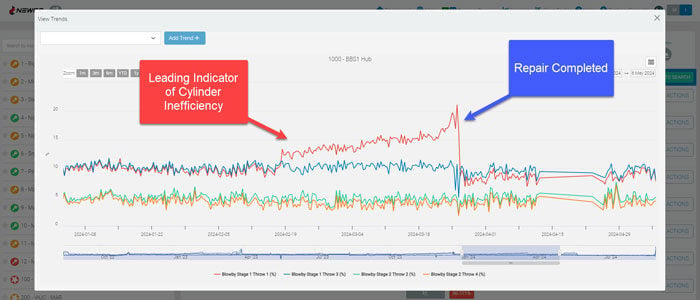

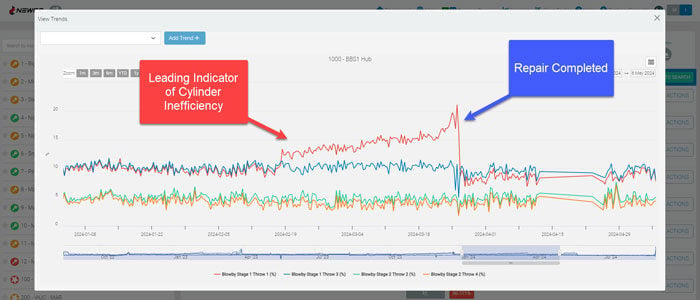

Failure Prevention

Optimize compressor configurations to mitigate risks and prevent failures across fleets.

Never Miss a Red Flag:

- Real-Time Reconfiguration: Address exceptions instantly to minimize risks.

- Instant Alerts: Make quick, informed repair decisions.

- Proactive Maintenance: Prioritize tasks strategically with throughput data.

- Comprehensive Monitoring: Access calculated and manufacturer-set limits.

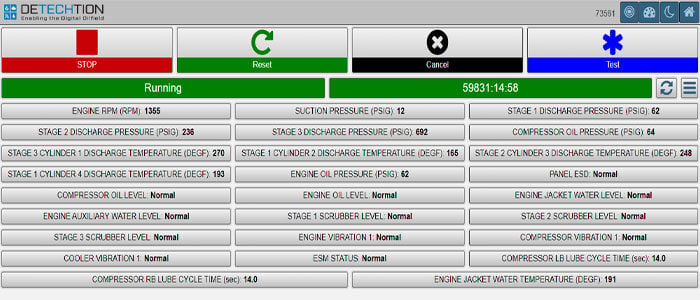

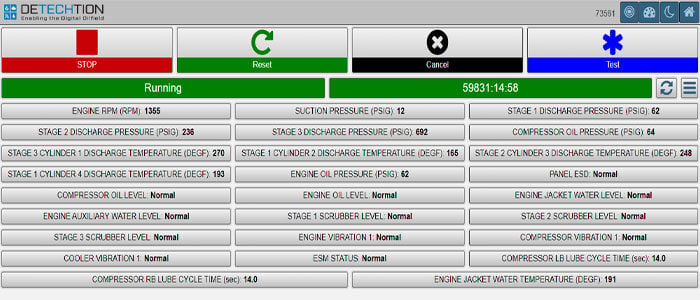

Control & Autonomy

Comprehensive automation ensures efficient, responsive, and secure compressor operations.

Give Your Operators Peace of Mind

- Over-the-Air Updates: 24/7 command for troubleshooting and usability.

- Remote Shutdowns: Improve safety and efficiency with fewer site visits.

- Performance Analytics: Control critical parameters with real-time insights.

- Dynamic Control: Optimize reliability with advanced package management.

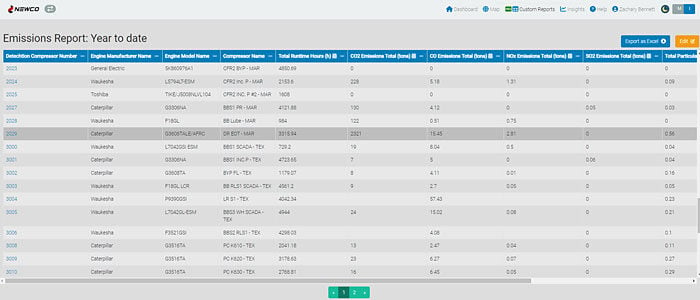

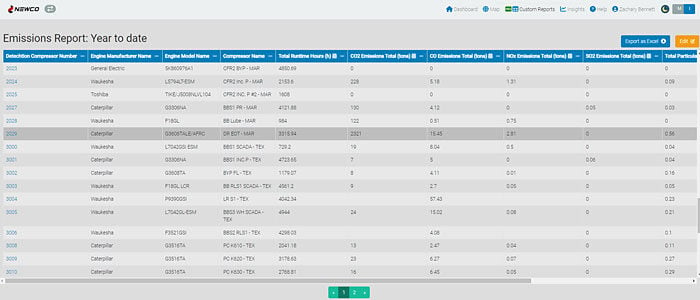

Emissions Reporting & ESG Solutions

Simplify emissions tracking and compliance to meet sustainability and ESG goals.

Effortless Sustainability

- Comprehensive Tracking: Monitor emissions across assets for better impact visibility.

- Seamless Compliance: Ensure accurate reporting and reduce penalties.

- Actionable Insights: Use emissions data to improve efficiency.

- Lower Tax Burden: Leverage accurate reporting for cost savings.

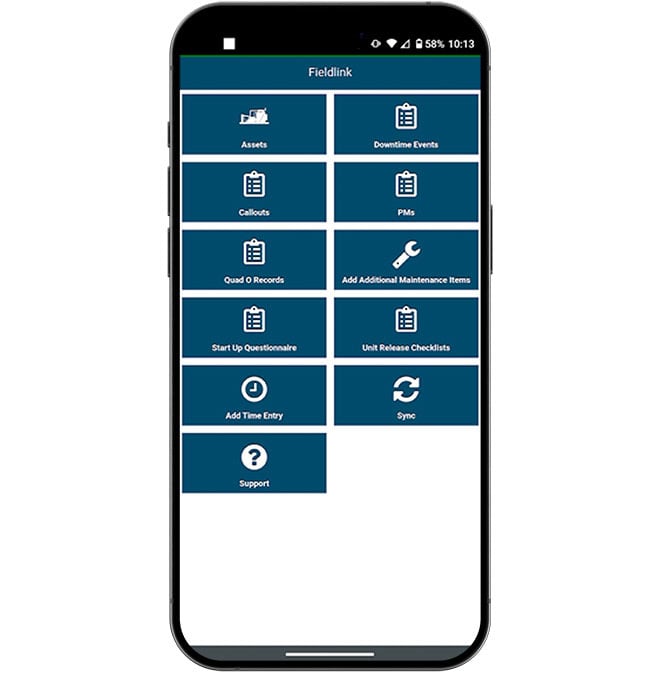

Compression Field Service Management

Simplify operations with a platform that integrates work orders, inventory, expenses, and emissions management.

How Detechtion Streamlines Management

- Integrated Systems: Enhance data flow with API-enabled environments.

- Automated Work Orders: Reduce downtime and improve workflows.

- Safety Reporting: Conduct JSAs, track incidents, and manage inspections.

Total Fleet Transparency Starts Here

Detechtion’s cutting-edge solutions enable proactive issue resolution, resource allocation and callout management through universal connectivity and real-time insights. Ready to always be in the loop?

Total Fleet Transparency Starts Here

Detechtion’s cutting-edge solutions enable proactive issue resolution, resource allocation and callout management through universal connectivity and real-time insights. Ready to always be in the loop?

Our Results Speak For Themselves

Explore how Detechtion technology revolutionizes compressor fleet management.

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.