Houston, TX |

Our Product Management team talks to users a lot… it’s a wonderful way to gather input for what to build (or improve) next. In conversations this spring, we learned that some great features already available in the latest (or even prior) versions of our products are things that our users don’t know about! I’d like to highlight three Enbase features that you might not know exist… and might want to use.

1. Setpoint integration

As of our Hub Distribution V2.0, released November 29, 2018, you can integrate your controller’s setpoints (HiHi, Hi, Lo, LoLo limits) with your Enbase Hub. In addition to mapping the Tag’s value to its Modbus register, you can also set the Modbus register(s) for any of your HiHi, Hi, Lo and/or LoLo values. You can also select whether the synchronization is one-way (controller to Hub) or bi-directional (changes on Hub push to controller and changes on controller push to Hub). Bi-directional synchronization has the advantage of allowing setpoint changes remotely from Enbase Dashboard! But even one-way synchronization helps to ensure that you can see the current setpoints as read-only via Enbase Dashboard without having to be onsite to know where your limits are set.

2. High-Frequency Data Logging

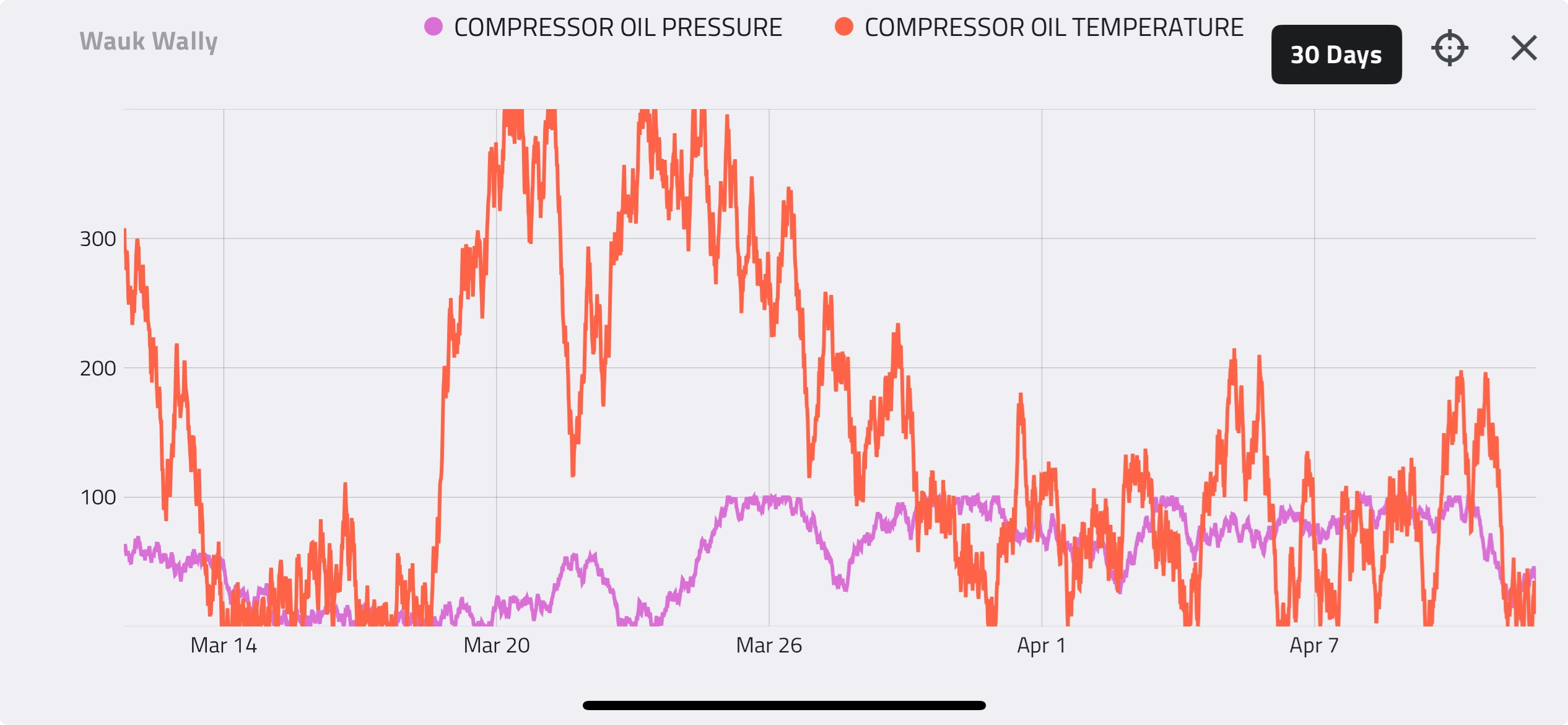

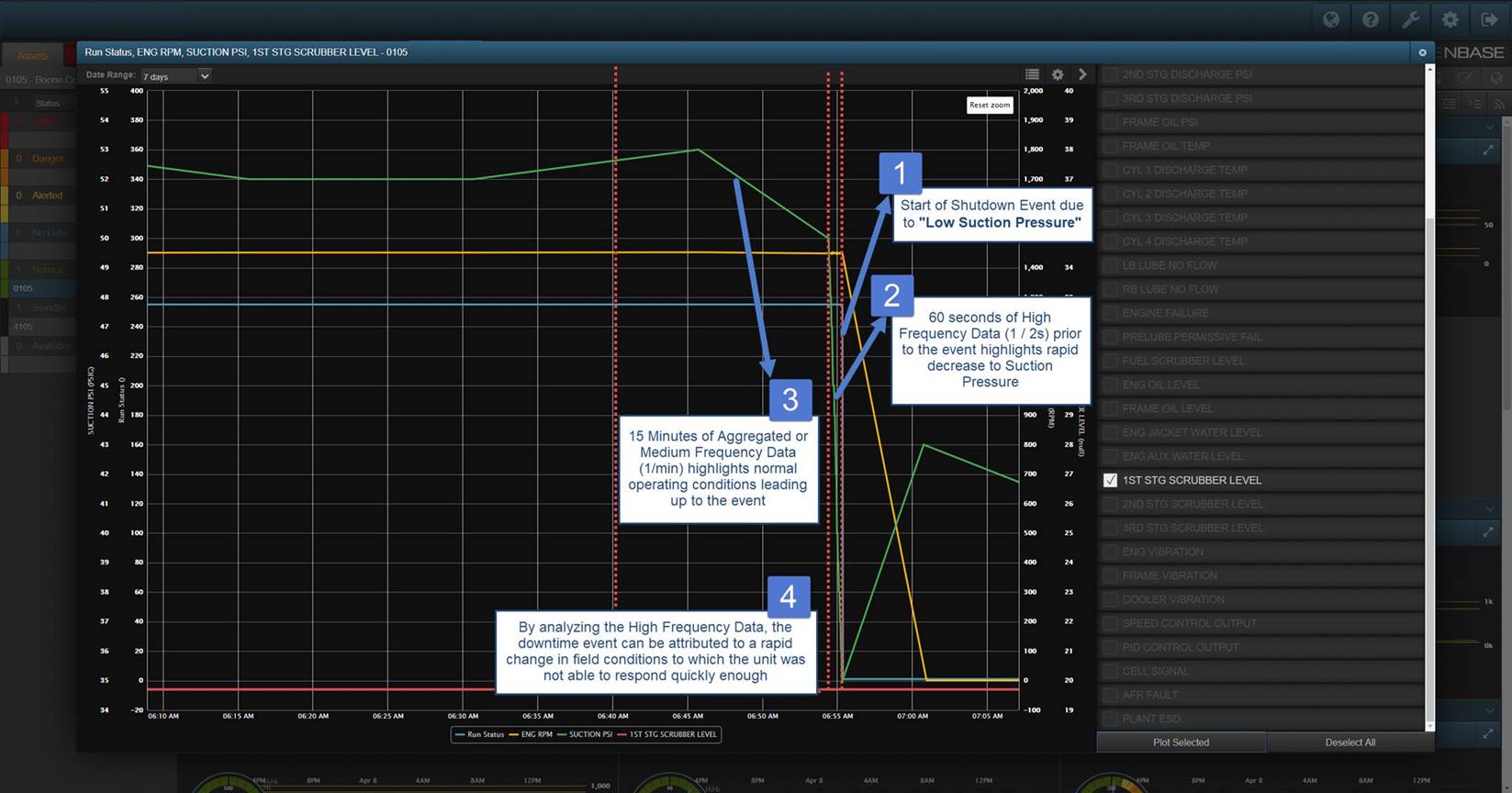

The Enbase Hub sends a value for each Tag to Enbase Dashboard every fifteen minutes when cell communications are sufficient. With the upgrade to Hub Distribution V2.0, higher-frequency data for the fifteen minutes prior to a shutdown is also sent to Enbase Dashboard…one data point per minute for the first fourteen minutes…then for the one- minute period just before the shutdown a data point every two seconds is sent. This is a total of thirty-three additional data points sent to help paint the picture of how the measurements changed, potentially shedding light on what may have caused the shutdown. This extra data available on the server can help tell the story of what happened. For example, did equipment fail due to wear or was the equipment run in a configuration that caused the failure, such as running a compressor with both suction and discharge valves closed? Trending pressures and temperatures in the seconds before a shutdown can help with understanding root cause. Note that if the Hub is communicating via satellite (e.g. cell tower is down or coverage is spotty), the high-frequency data sent is limited to the six seconds prior to the shutdown, or three additional data points.

3. Engine Monitoring

Did you know that your Enbase Hub can monitor your engine panel as well as your compressor controller? The Enbase Hub can monitor any engine controller with Modbus or CAN bus connection, such as a Caterpillar ADEM III/IV and Waukesha ESM. It can also monitor digital or analog inputs or thermocouples with the addition of the Enbase Expansion I/O Module. In addition to engine monitoring, it can even monitor additional devices/equipment such as production flow meters or tank level sensors monitoring lube oil levels.

Are there new features you are excited about? Are there features you think we should add? We’d love to hear your thoughts at productmanagement@detechtion.com.