Houston, TX |

With each day that passes, the urgency to implement policies focused on combatting climate change grows.

Federal and state governments are introducing more policies and guidelines that require vast cooperation from oil, gas, and industrial chemical companies to slow the negative environmental consequences of energy production.

The big ask: How do you simultaneously leverage operating efficiency and minimize environmental impact?

Participation in Environmental & Social Governance (ESG) standards is more than an attempt at public relations management.

The industry is called to reevaluate established workflows, ticketing systems, and ops management practices (some dating back 30-40 years) throughout their organizations to establish effective & scalable programs that pass local requirements. Finding low-cost, high-impact opportunities for efficiency gains is a crucial step for O&G companies to save themselves emissions and expenses through decreased carbon levies or their equipment’s electricity usage and fuel gas consumption.

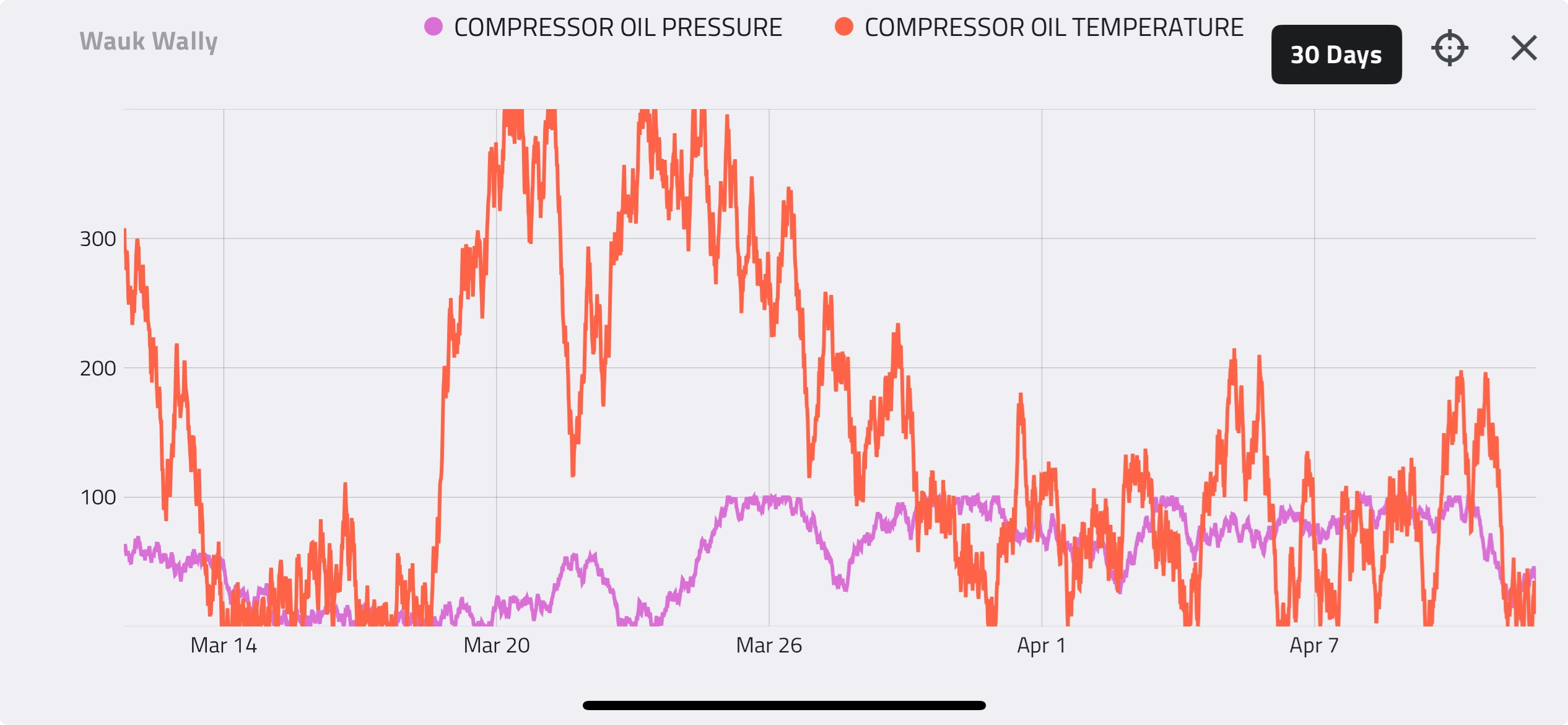

Some of the biggest culprits for lofty expenses and emission issues are production units that have been sub-optimally configured in remote locations. Compressors and chemical injection systems that have not been set up or monitored correctly can often experience minor issues that go unnoticed until a major breakdown occurs in the field.

Leading up to an unplanned outage, the unit could be quietly wasting power and releasing unnecessary emissions resulting in high maintenance costs and fines.

By implementing Asset Performance Management software (APM) with remote monitoring infrastructure and predictive maintenance programs, companies can confidently manage by exception to save time, money[1], and run an effective ESG program. Offsite personnel using APM as their main optimization tool cite less unplanned callouts, more efficient production, and the ability to avoid excessive downtime per unit.

In 2015, Detechtion Technologies calculated that its customer base eliminated over 600,000 metric tons of annual CO₂ emissions (equivalent to 130,000 passenger vehicles in North America1[2]) by optimizing their compressor fleet with Enbase cloud-based Asset Performance Management (APM) software.

“The primary value of APM is identifying opportunities to increase utilization in compressor fleets. It is equally important to increase efficiencies, save power consumption, and reduce carbon emissions without sacrificing production,” Kirk Hanes, Chief Revenue Officer for Detechtion, said. “I was pleased we commissioned such a study to quantify just how much the industry as a whole were helping to affect these increasingly important metrics.”

[1] By integrating the Enbase Hub edge device to Enalysis™, Detechtion’s APM, customers reported a 6% reduction in fuel costs by avoiding unplanned callouts.

[2] According to the Environmental Protection Agency (EPA), the typical passenger vehicle emits about 4.7 metric tons of CO₂ per year.