Houston, TX |

This E-Tip is the first in a series that will cover the basics of natural gas compression. While compressors are complex machines, this series will strive to simplify the key concepts of concern when dealing with the compression of natural gas in a reciprocating or screw compressor. From the basics of the relationships between volume, pressure and temperature of a gas, this series will develop an understanding of capacity and power for compression and the key variables that influence both.

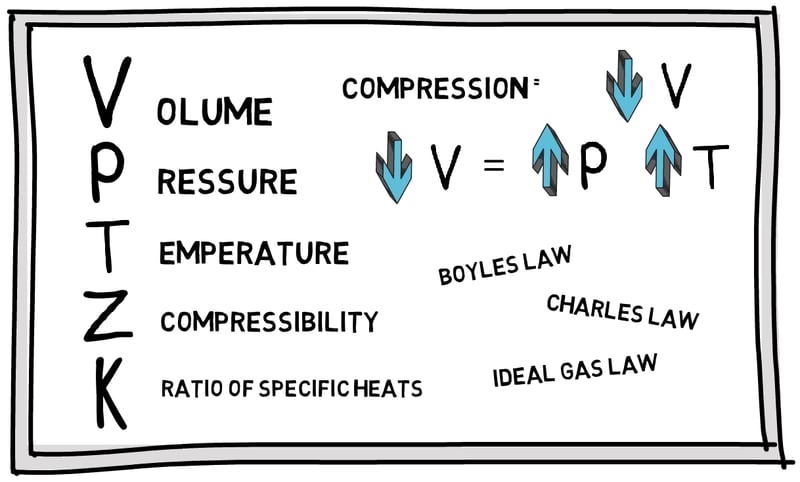

First, we will simplify compression to the reduction of a known volume of gas to discuss the relationship between Volume, Pressure, and Temperature. This should take you back to high school with memories of Boyles Law and Charles Law.

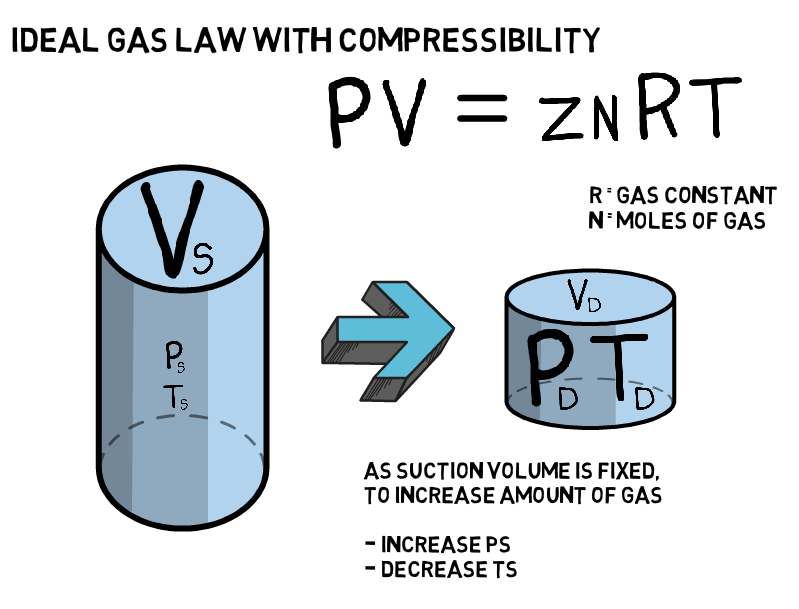

Next, we will throw in the properties of the gas being compressed to the mix with the Ideal Gas Law and compressibility. The law quantifies the number of molecules of gas that can fit into a defined volume under known conditions, which is important in gas compression as we try to move as much gas as possible.

Next, we will throw in the properties of the gas being compressed to the mix with the Ideal Gas Law and compressibility. The law quantifies the number of molecules of gas that can fit into a defined volume under known conditions, which is important in gas compression as we try to move as much gas as possible.

The simplified volume used above is defined by the physical dimensions of a compressor’s cylinders (or rotors in the case of a screw) and, when multiplied by the running speed, RPM, is essentially the compressor’s Displacement. However, a compressor’s gas Capacity depends on how many molecules of gas will fit into this displacement volume, which is influenced by the Pressure and the Temperature, but also how much of the displacement is useable.

Not all the displacement can be filled with gas that will eventually be discharged from the cylinder. This ratio of capacity to displacement is called the Volumetric Efficiency, which is influenced by the Clearance volume of the cylinder (think VVCP, pockets, spacers, etc) and the Compression Ratio. While a screw compressor does not have any way to adjust clearance, the capacity can be reduced relative to the displacement by opening the Slide Valve.

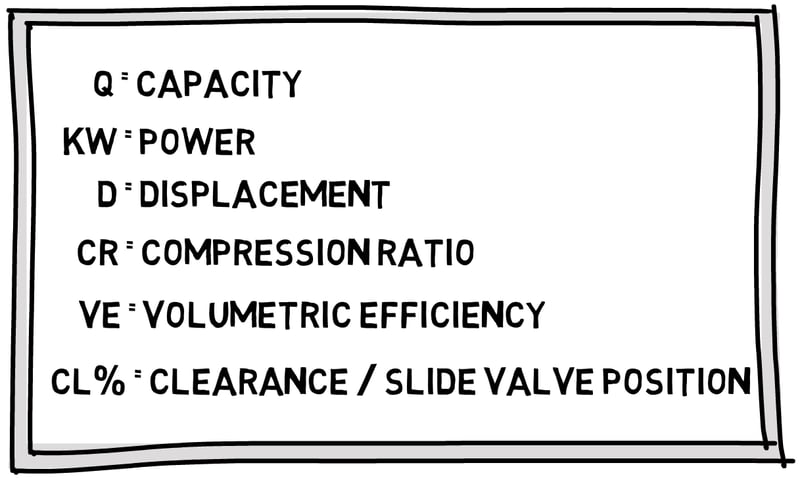

Finally, compressing the gas requires energy. This energy comes from a driver and, for reciprocating and screw natural gas compressors, this driver is most often a natural gas driven engine or an electric motor and is expressed as power in either Kilowatts or Horsepower. The amount of Power required for compression depends on the amount of gas being compressed, Capacity, and the pressure range through which the gas is to be compressed, Compression Ratio.

So, while the engineering calculations defining gas compression are complex, this series of E-Tips will show how a solid understanding of compressor performance can be achieved through the understanding of a gas’ behaviour to changes in pressure and temperature and that:

Capacity (Q) is function of

Displacement (D) and Volumetric Efficiency (VE%)

Volumetric Efficiency (VE%) is a function of

Clearance (CL%) and Compression Ratio (CR)

Power (KW/HP) is a function of

Capacity (Q) and Compression Ratio (CR)

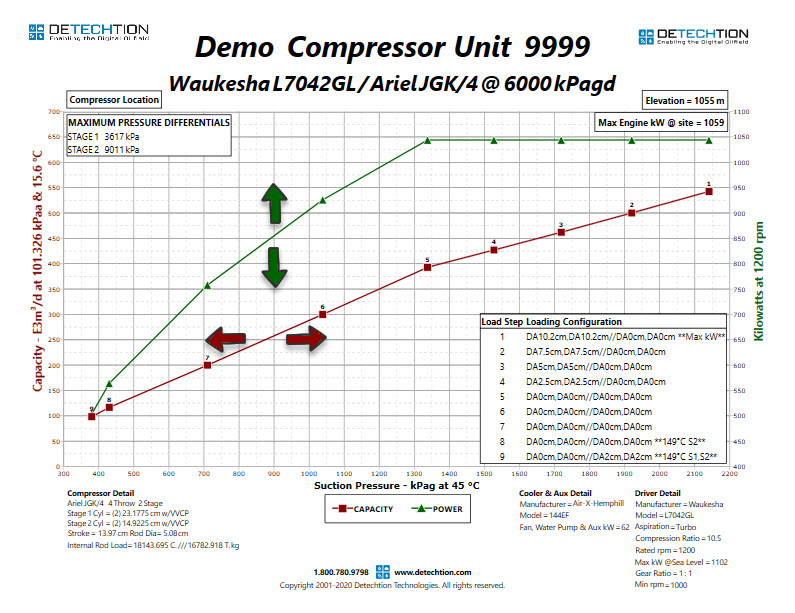

In developing the above relationships, these E-Tips will use the concepts to explain the operating range of compressors and why performance curves look the way they do. As well, they will look at how changes in parameters shift the performance curves, increasing or decreasing capacity at a given suction pressure or requiring more or less power to compress a given volume of gas. This is a key concept to understand the effect of changing conditions, such as suction temperature and discharge pressure, as well as why a change of pocket (VVCP) position elicits a certain outcome from the compressor (or, maybe, why it did not!).

In the second E-Tip in this series, Enalysis Tip 1.17: Natural Gas Compression Basics 1 - Gas Properties, we will explore some basic gas properties to see how gases respond to changes in pressure and temperature and what that means for the amount of gas that can fit in our compressor at suction conditions.

For more E-Tips, please visit the Detechtion Technologies Learning Center.