Houston, TX |

Enalysis Version 5.0 is now live and offers a new and greatly improved user experience allowing customers to better identify, investigate and act on valuable opportunities for improving their assets’ and fleets’ performance. In addition to improving the overall user experience, Enalysis Version 5.0 is built on an entirely new platform dramatically improving the software’s scalability, ability to deliver new features in a rapidly evolving market, and capability for users to work seamlessly on their mobile devices.

This post is part of a series aimed to showcase how Enalysis Version 5.0 will improve how you can deliver value to your company. The focus for this post is to walk through how a user can identify, investigate and evaluate production optimization opportunities utilizing the latest version.

Background on Production Optimization Opportunities

Production optimization opportunities can be classified as situations where a compressor can potentially move more gas at the same suction pressure, or when a compressor can move the same amount of gas, but at a lower suction pressure. In the first scenario, when the gas is available, allowing the compressor to move more gas can result in a direct increase in revenue and an immediate benefit to our clients. In the second scenario, if the well-deliverability favors lower suction pressures, reducing the suction pressure can potentially result in incremental production gains as well.

Identifying Production Optimization Opportunities

To first identify a production optimization opportunity, Enalysis V5.0 has made it much easier to identify and investigate opportunities within your compressor fleet. Enalysis V5.0 surfaces opportunities across your fleet to effortlessly identify what assets present optimization opportunities on the Dashboard. Utilizing the capabilities of the dashboard, you can drill further into your assets to look in depth at the assets that contribute to the opportunities available to you.

The following video outlines how you can navigate between a fleet level overview to an asset-by-asset overview which allows our users to identify the opportunities presented to them. In the following example, Enalysis has identified a compressor with a production optimization opportunity of $39,000/month increase in revenue based on a $1/mscf gas price.

Investigating Production Optimization Opportunities

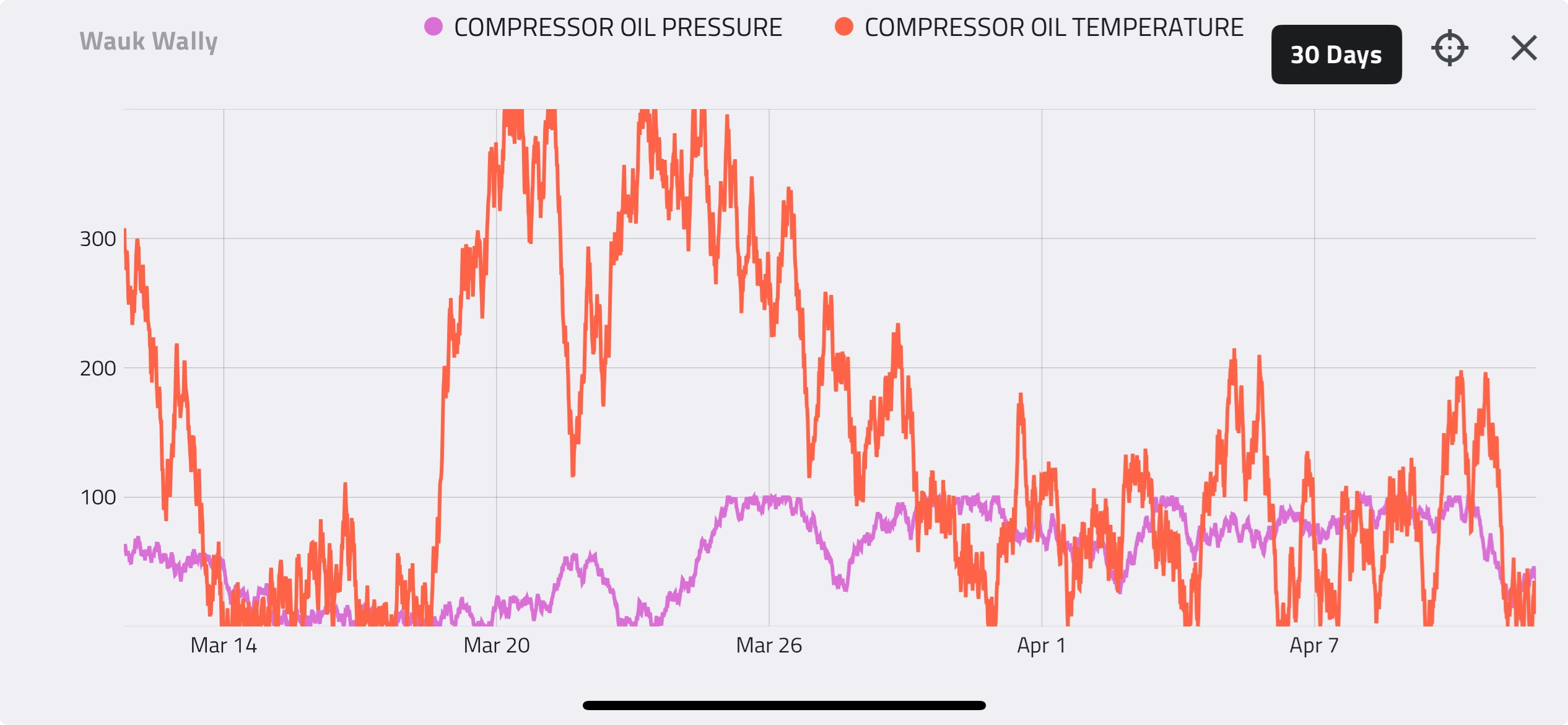

When you've identified an asset that presents an opportunity to optimize, utilize the vital signs to assess the performance and operating conditions of your asset. To understand the performance of your equipment, you will want to understand the expected and desired operating range of your equipment.

The following example highlights the types of details we would be looking to capture to then move onto the evaluation step.

| Parameter | Value (Current) | Value (Target) |

| Suction Pressure (psig) | 33 | 33 |

| Discharge Pressure (psig) | 550 | 550 |

| Production (mmscfd) | 6.5 | 8.0 |

| Capacity (mmscfd) | 8.0 | 8.0 |

| Incremental Production (mmscfd) | 1.5 | 0 |

The goal based on the data is to maintain the current suction pressure and increase the production of the compressor.

The following video outlines how you can navigate from the fleet level overview to drill into the asset of your choice to determine the optimization potential.

Evaluating Production Optimization Opportunities

When the goal has been determined, the simulator can then be leveraged to determine whether the optimization can be achieved. The goal in this case is to determine if adjusting the configuration will allow the machine to increase production while maintaining the same suction pressure. To perform the simulation, a user can navigate directly from vital signs to the simulator. For performing the simulations, please refer to the following post for details: Performance Modeling with Enalysis Simulator

The outcome of the simulation exercise indicates that production and pressures can be maintained while reducing total fuel usage from 67mscfd to 24mscfd by reducing the assets total capacity. The capacity reduction is achieved by reducing the speed to the drivers minimum speed of 1200, and further capacity reduction by opening pockets and non-acting one of the first stage cylinders.

| Parameter | Value (Current) | Value (Target) | Change | Comment |

| Suction Pressure (psig) | 33 | 3 | - | No suction pressure increase |

| Discharge Pressure (psig) | 550 | 550 | - | |

| Production (mmscfd) | 6.5 | 8.0 | - | |

| Running Speed | 1200 | 1200 | - | |

| Configuration | DA1.5",DA1.5"//DA0"//DA0" | DA0",DA0"//DA0"//DA0" | S1 Pockets Closed | Closing pockets maximizes compressor appetite |

| Capacity (mmscfd) | 8.0 | 8.0 | - | Compressor can move up to 8.0mmscfd at the same suction pressure |

If the new configuration is deemed promising, utilize the "send to engineer" functionality to receive a more in-depth review of the assets limitations, and guidance on how to set the compressors operating set points.

The following video outlines how you can utilize the Enalysis simulator in combination with the operating data from the assets vital signs to evaluate the validity of the opportunity.