Houston, TX | February 14, 2024

Discover the Future of Compressor Control—Watch the Webinar On-Demand and Sign up to be an Early Adopter!

Managing a compressor fleet has never been more challenging. With fewer operators in the field, outdated control systems, and untapped production potential, companies are leaving revenue on the table. But what if there was a smarter way to optimize compressor performance, reduce downtime, and maximize efficiency—all in real-time?

Enter SkidIQ Adapt, a cutting-edge solution developed through the alliance between Waukesha Gas Engines and Detechtion Technologies. In our recent webinar, we explored how SkidIQ Adapt is transforming compressor management by delivering dynamic, intelligent control that goes beyond traditional static configurations.

If you missed the live session, you can now watch the full webinar on-demand to dive deeper into the technology, real-world use cases, the significant business impact of SkidIQ Adapt, and discover the perks of being an early adopter!

What did we cover?

The Challenges in Compressor Management

For over 30 years, Detechtion has been working with compressor fleets, and one thing is clear—managing these assets is hard. Many operators face common challenges, such as:

- Preventable Shutdowns – Many compressor control systems don’t proactively prevent failures, leading to unnecessary downtime and lost production.

- Underutilized Assets – Compressors are often configured too conservatively, limiting their ability to respond to changing field conditions and reducing overall throughput.

- Limited Field Resources – With fewer operators in the field, shutdowns take longer to resolve, increasing maintenance costs and reducing efficiency.

- Data Overload or Data Gaps – Some operators have too much data to interpret, while others lack the insights needed to prevent failures and optimize performance.

These challenges directly impact profitability, leading to lost revenue opportunities, higher maintenance costs, and reduced equipment lifespan.

So, how do we fix this?

How SkidIQ Adapt Delivers Smarter Control

Traditional compressor control systems operate with fixed setpoints, much like basic cruise control in a car. This static approach forces compressors to work within predefined limits, regardless of real-time conditions—often sacrificing efficiency, production, and reliability.

SkidIQ Adapt takes a different approach. Using real-time data, advanced control algorithms, and digital twin technology, it enables compressors to adapt dynamically to changing conditions, unlocking new levels of performance.

Here’s how:

- Optimized High-End Operating Range – SkidIQ Adapt enables compressors to take advantage of higher gas volumes, leading to incremental production gains.

- Improved Low-End Utilization – The system dynamically adjusts control parameters to pull harder on the field at lower pressures, increasing efficiency and reducing fuel consumption.

- Real-Time Adaptive Control – Instead of relying on conservative fixed setpoints, SkidIQ Adapt monitors performance continuously and adjusts key parameters to maintain optimal operations.

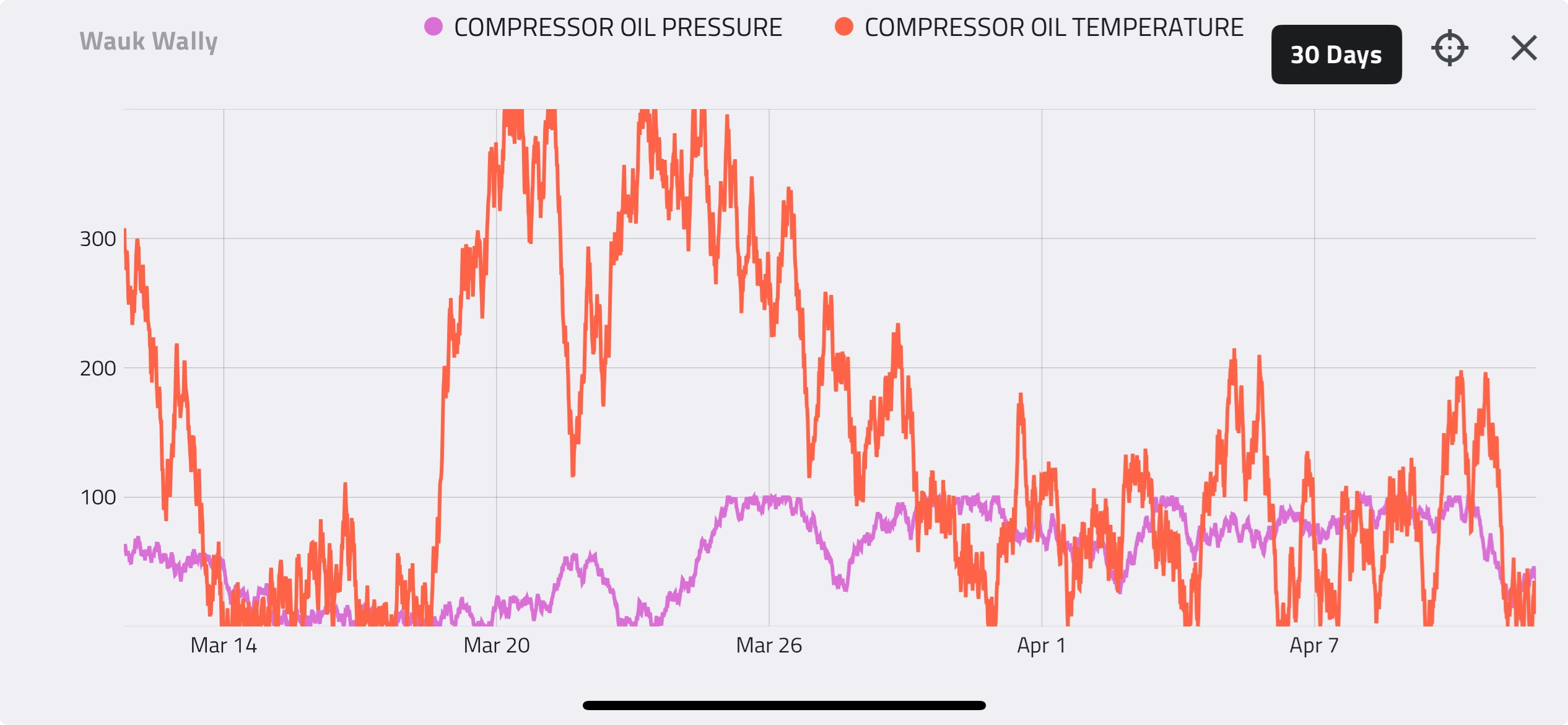

- Proactive Shutdown Prevention – By integrating real-time analytics with compressor control, the system identifies potential failures before they happen, significantly reducing unplanned downtime.

- Seamless Engine-Compressor Integration – As a fully integrated control system between Waukesha ESM2 engine controllers and compressor control, SkidIQ Adapt offers a single, unified interface for monitoring and optimization.

Real Business Impact: More Production, Fewer Shutdowns

The numbers speak for themselves. Our analysis of real-world compressor data shows that many assets are leaving significant value on the table.

📈 A single compressor unit was found to be holding back up to $250,000 per year in potential production due to static control configurations.

📊 Across an entire fleet, further analysis identified $10 million per year opportunity for increased gas throughput across 20 assets.

By eliminating pinched-back horsepower, optimizing control parameters, and reducing unnecessary shutdowns, SkidIQ Adapt will help operators:

- Increase utilization by 2% – More utilization means more gas processed and higher revenues.

- Prevent 2 shutdowns per month – Reducing costly downtime improves operational efficiency.

- Increase Revenue by $150,000+ per year – Through a combination of increased production and lower maintenance costs.

Why SkidIQ Adapt? What Sets It Apart?

Unlike traditional compressor control systems, SkidIQ Adapt is built for the modern oil & gas environment.

- Fully Integrated Package Controller – The only solution that seamlessly integrates compressor and engine control into one system.

- Digital Twin Running on the Edge – Real-time analysis and control based on actual asset performance, ensuring safety and maximum utilization.

- Proactive Shutdown Prevention – Advanced PID Control logic uses an extensive set of standardized process variables to identify potential failures before they happen, and prevent unnecessary shutdowns.

- Remote Monitoring & Control – Secure, SOC 2 Type II compliant remote access lets operators adjust settings, start/stop assets, and optimize performance from anywhere.

- Total Fleet Control – Built on Detechtion’s industry-leading fleet management expertise, enabling operators to unlock hidden performance across their entire fleet.

- Dedicated Expertise & Support – Backed by Waukesha and Detechtion’s combined 100+ years of experience in engines, compression, and automation.

Now Accepting Early Adopters – Get Involved!

As of January, 2025, Detechtion and Waukesha are currently offering a limited-time early adoption program for SkidIQ Adapt. Eligible operators will receive significant benefits.

If you’re looking for an easy way to upgrade your compressor control system and unlock significant efficiency and production gains, now is the perfect time to get involved.

Spots are filling up fast, so don’t miss this opportunity!

Watch the Full Webinar to Learn More

Want to dive deeper into how SkidIQ Adapt can optimize your compressor operations?

🎥 Watch our full webinar on-demand to explore:

🔹 Real-world case studies demonstrating the financial impact of adaptive control

🔹 Technical deep dive into how the system works

🔹 Live Q&A session answering key questions from industry professionals

👉 Register now to watch the webinar!