Houston, TX |

Welcome back to our ongoing journey through the world of compressor fleet management. In our second episode, hosted by Zachary Bennett with special guest Chiminh Trac from Detechtion, we explored the critical theme of optimizing compressor fleets to boost production. This session delved into practical insights and shared a compelling case study demonstrating significant improvements in fleet operations.

If you missed the live session, you can watch on-demand here:

Recap

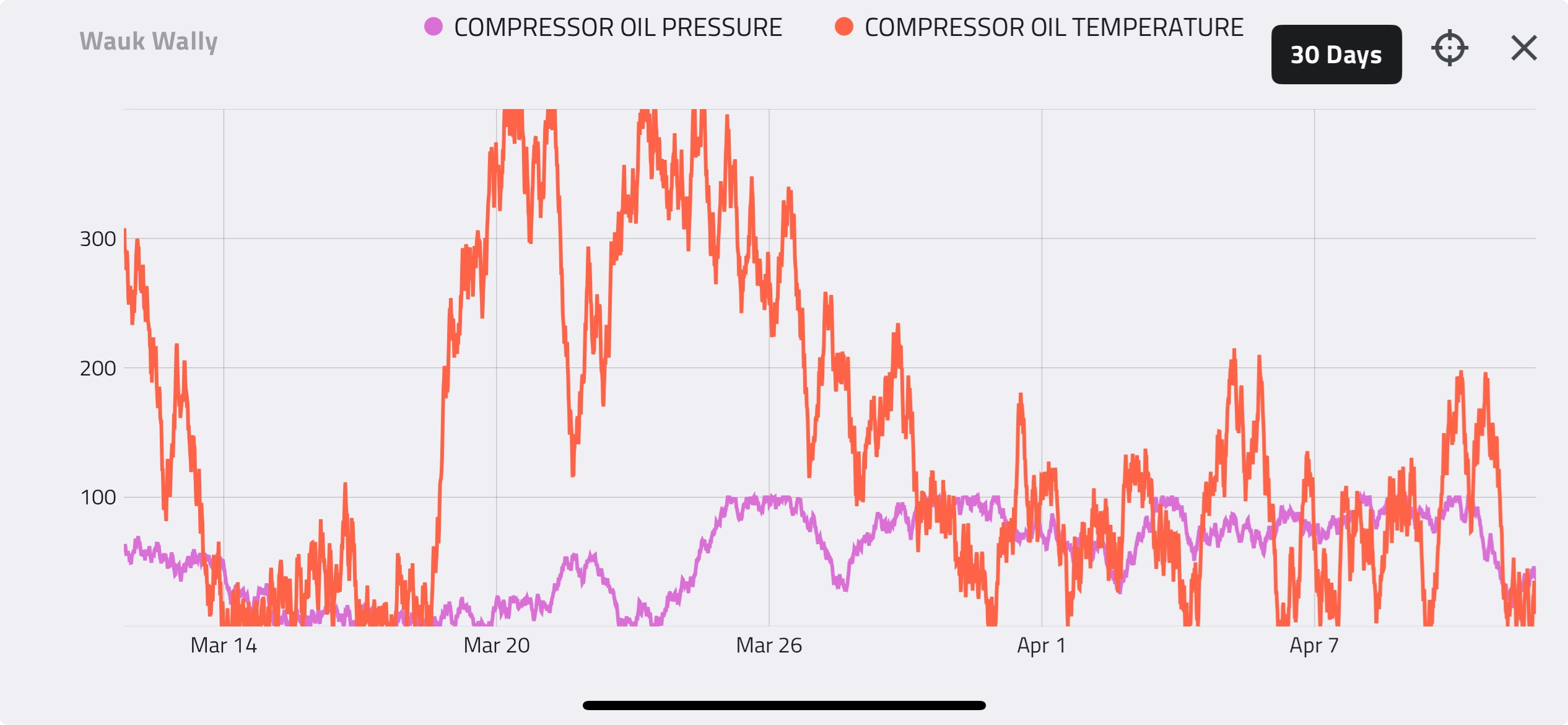

The focus of this episode was primarily on the optimization life cycle, which is fundamental to enhancing the efficiency and output of a compression fleet. We discussed how starting with robust data collection forms the backbone of any successful optimization strategy. In this session, Chiminh introduced us to how Detechtion leverages operational data such as running speeds, cylinder pressures, temperatures and cylinder configurations to drive analytical processes. This raw data is then combined with the assets geometric model through the Digital Twin to generate insights, which is made available through Enalysis.

The highlight of the episode was a detailed case study where the client was able to identify, evaluate and implement an optimization opportunity for an under-utilized asset. In this study, the client was facing underutilization of a compressor asset identified through low horsepower and cylinder capacity utilization. By adjusting the stage one cylinder pockets, the client was able to increase the utilization of the asset. By increasing the utilization, the unit was able to pull harder on the field resulting in a reduced suction pressure. This lower field pressure resulted in a throughput increase of 7%, or 7 e3m3/d (247 mscfd). A substantial production increase for a relatively simple configuration and set point adjustment.

Key Insights and Takeaways

Our discussion underscored the importance of evaluating and reconfiguring compressor settings to match operational demands efficiently. The 'what-if' scenarios, simulated through Detechtion's software, demonstrated how different configurations could lead to improved asset utilization and operational cost savings.

REgister for Episode 3

To register for the next episode in the series hosted on August 28 @ 12:00pm MT / 1:00pm CT, click here: