Houston, TX |

In the fourth episode of our Know Pressure: Your Guide to Compressor Fleet Management webinar series, host Zachary Bennett sat down with Detechtion’s own Aubrey Milliron to discuss an essential topic for the oil and gas industry: compressor fleet reliability. With a wealth of field experience under his belt, Aubrey shared case studies and practical insights on how technology can prevent unscheduled downtimes, reduce costs, and optimize operations.

If you missed the live session, you can watch on-demand here:

Brief Overview

What is Reliability?

Reliability in compressor operations is the ability of equipment to perform consistently without unexpected failures. This becomes crucial in the field where unscheduled shutdowns don’t just disrupt operations but also lead to costly downtimes and emergency part replacements. As Aubrey noted, addressing these challenges can save operators time, labor, and substantial operational costs.

Using Data and Technology for Reliability Improvement

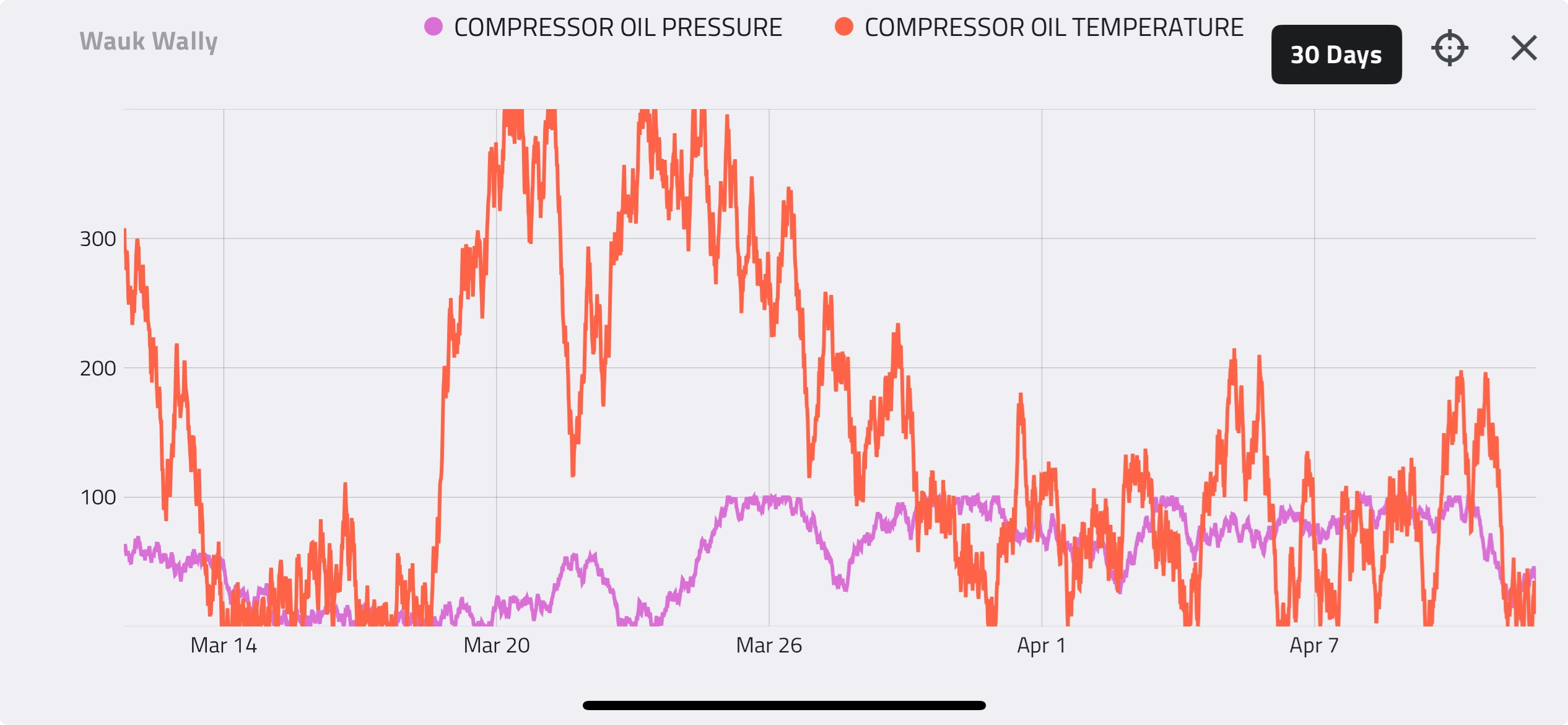

Aubrey highlighted a proactive approach to improving reliability through technology, explaining how comprehensive data acquisition, analysis, and monitoring can detect potential issues before they cause shutdowns. He shared a diagnostic framework that includes collecting raw data, generating performance metrics, using modeling, and validating fixes to ensure operational improvements stick.

Case Studies: Real-World Applications

In this session, Aubrey shared two real-world examples that showcased how Detechtion’s solutions prevent and troubleshoot equipment failures. Here are the highlights:

-

Rod Load Failure Case

- Issue: A rod load exceeded its limits, causing severe equipment damage.

- Solution: By examining data and pinpointing the root cause, Aubrey and the clients operations team identified inefficiencies in the compressor’s second and third stages. The team recommended repairs and adjustments, preventing further costly shutdowns.

-

Preventing a Potential Failure

- Issue: During a daily review, Aubrey noticed early warning signs of high rod load and blow-by in another unit.

- Solution: Leveraging high-resolution data captured by the Enbase Hub, the operations team was able to identify and fix damaged valves and replace a plugged witches hat. This proactive and exception based maintenance prevented a major failure, enabling uninterrupted production and minimizing expenses.

Key Takeaways

For Aubrey, the session’s main takeaway was clear: reliable compressor operations are built on data-driven decisions. Frequent, high-resolution data provides operators with the insights needed to catch issues before they escalate. When paired with Detechtion’s digital twin simulation, operators gain a predictive tool for anticipating performance and scheduling preventive maintenance. Aubrey emphasized that adding differential pressure switches and using customized startup packages for units are effective ways to further prevent costly failures.

Register for Episode 5: Optimizing for Emissions

To register for the next episode in the series hosted on December 4 @ 12:00pm MT / 1:00pm CT which is focused on Emissions Management and Compliance, click here: