Houston, TX |

Blowby, can indicate inefficiencies due to a few different reasons, but for the scope of this blog post, in the simplest of explanations, Blowby in this context is a measure of the health of your cylinders and can be an indicator of your compressor valve and piston ring health. Here are some reasons why catching bad valves earlier than later would be advantageous and contribute to safer environment for your operations and maintenance staff:

- A bad 1st stage valve reduces the capacity of your compressor. The gas that doesn't get into your 1st stage doesn't get to sales, losing you money

- A bad valve on an upper stage can shift enough compression work onto the previous stage, causing high rod loads leading to lost production and expensive repair costs

- If pieces of a bad valve or the springs get into the cylinder while in operation, this can lead to severe damaging of your cylinder lining (as shown below), leading to lost production due to downtime and expensive repair costs

- In the rare, but possible, event that you lose a corner of valves, especially discharge valves, your cylinder is now effectively single-acting which can push that cylinder into a non-reversal situation, leading to minimal lubrication at the cross-head pin, resulting in a very serious failure.

Assuming that you are taking your suction/discharge pressures and temperatures in the recommended spots, and all orifice plates are taken into account, Blowby can give an accurate indication as to when your valves or piston rings are starting to fail. As your piston rings fail, hot gas at the end of your compression process leak to the other end of the cylinder (piston rings damaged), back into the suction port (suction valves damaged), or back into the cylinder (discharge valves damaged). The leaked "hot gas" elevates the suction temperature, resulting in a much higher discharge temperature than expected, and Blowby will be calculated as a positive value.

Recommended Action Items:

- When you see blowby, we recommend collecting a new set of data to confirm whether or not it was an anomaly in the data, as well as shoot your valve caps to see if any of them seem to be hotter than the others.

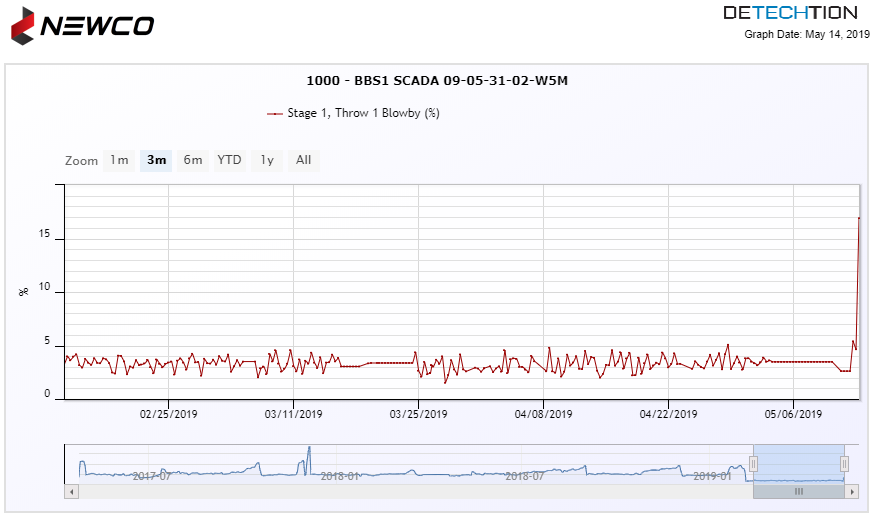

- Open the Enalysis Report on the website and take advantage of the "trending" functionality. If your blowby trend has a spike (as shown below), this may indicate a very fast valve failure that may be due to liquid carryover, or bad data. If your blowby trend has shown a progressive increase in blowby, this may support that your valve health and performance has deteriorated.

- When you see blowby, if you're unsure, or want a second set of eyes on things, reach out to your Engineering Account Manager to see what they are seeing from the various trends.

- If all the checks support that some work ought to be done, align the shutdown with an existing planned shutdown if possible to keep any unscheduled downtime to a minimum.

If you have any questions about this topic of conversation, or want to learn how Detechtion Technologies may be able to help your operations achieve Operation Excellence, please do not hesitate to reach out!