Preventative Maintenance (CMMS)

Minimize Downtime, Maximize Reliability

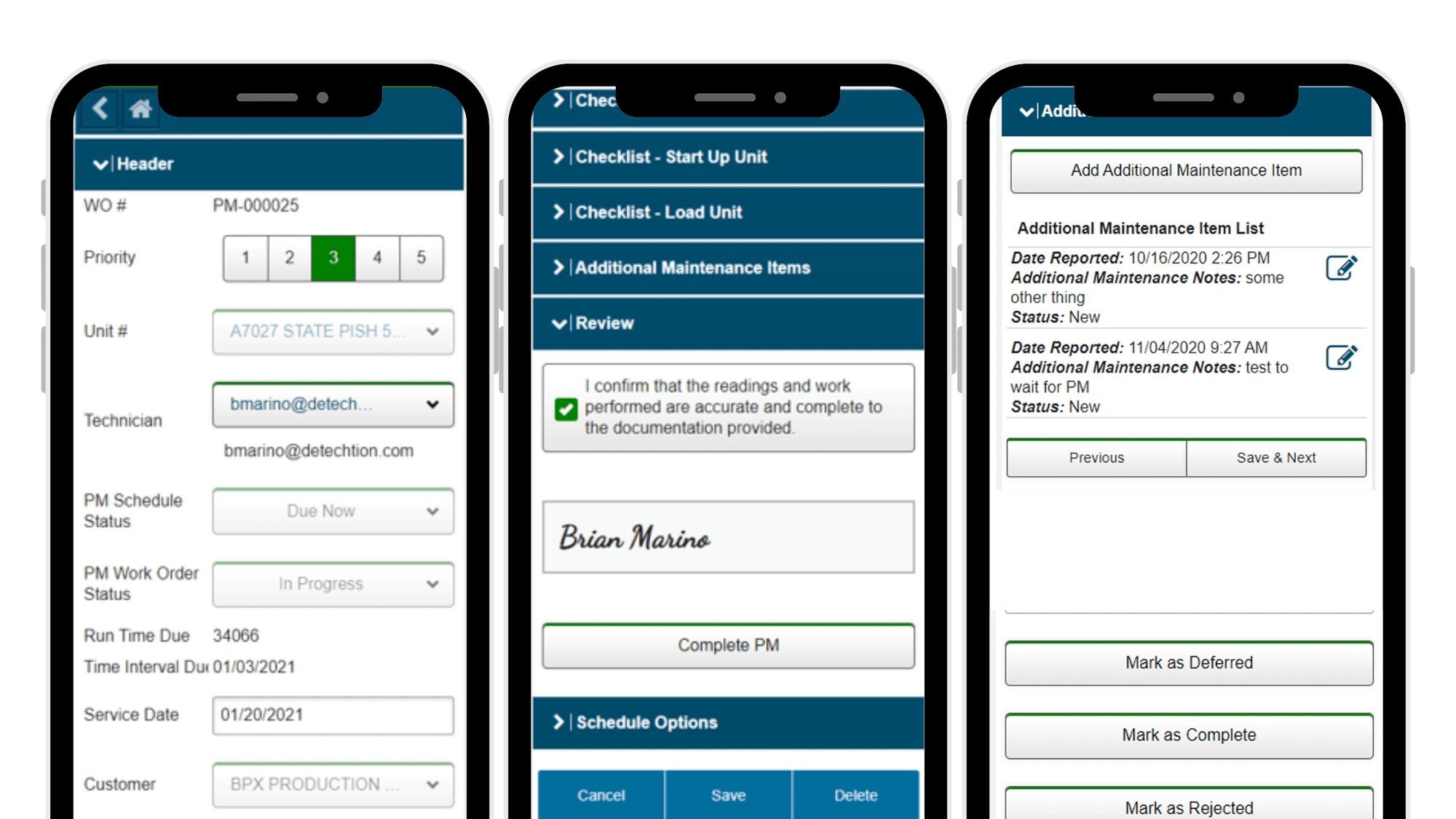

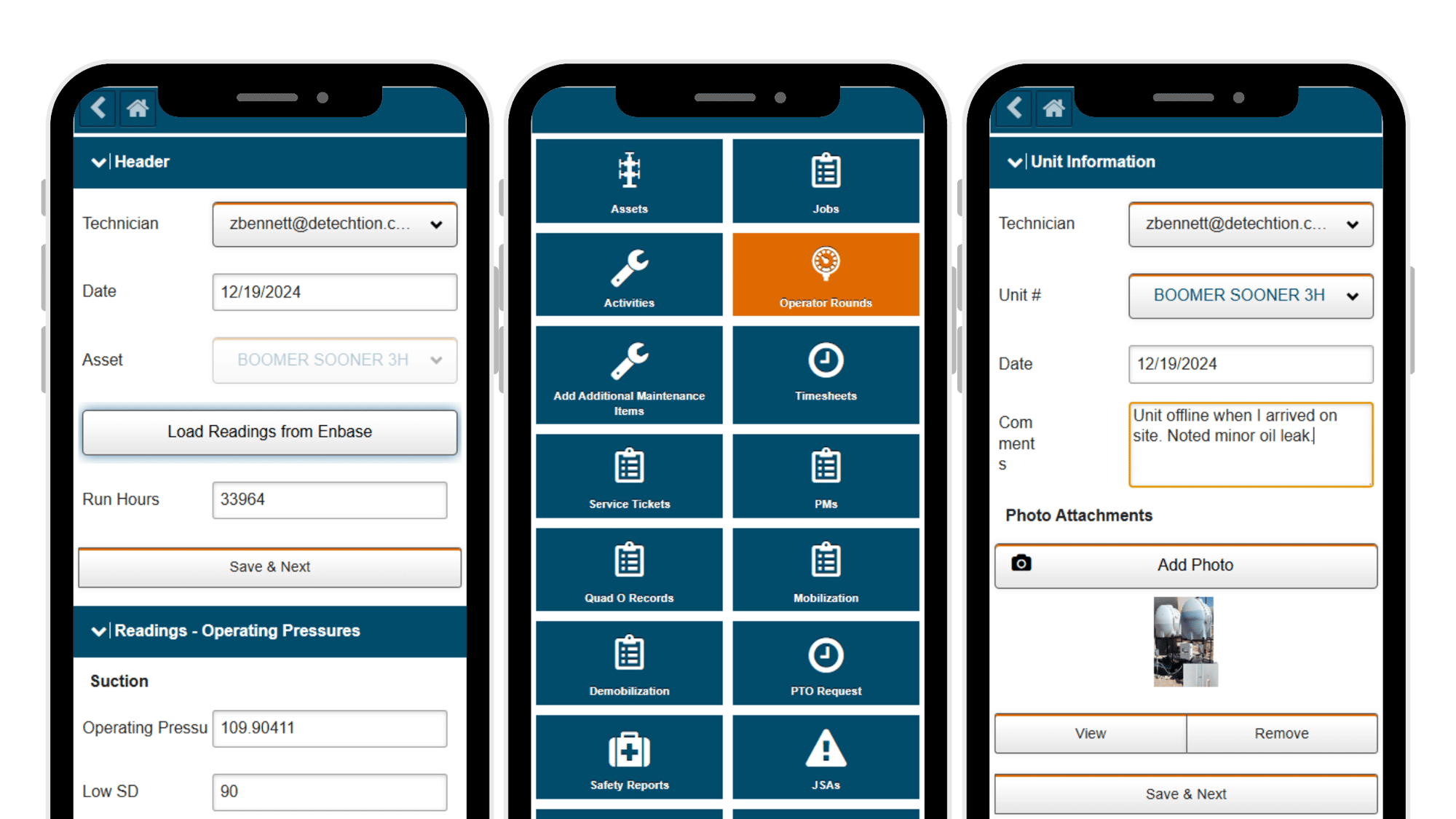

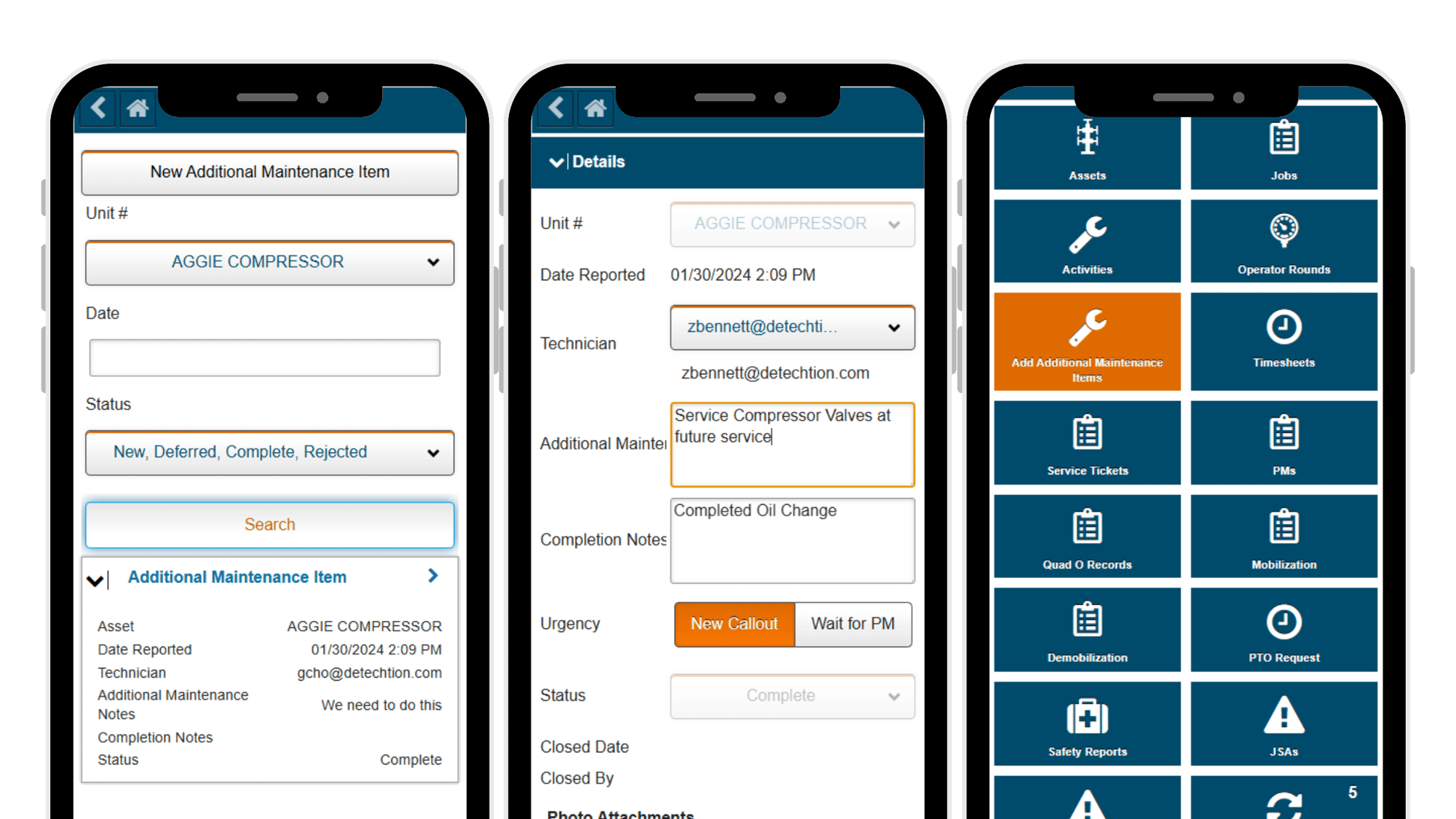

Preventative Maintenance solutions by Detechtion transforms maintenance management from reactive to proactive, reducing unplanned downtime and costly repairs. With advanced scheduling tools, real-time equipment monitoring, and compliance-ready documentation, your team can ensure operations run safely and efficiently.

Prevent Downtime and Keep Operations Running Smoothly

How can oilfield teams stay ahead of equipment failures and manage maintenance schedules efficiently?

Preventative Maintenance solutions by Detechtion centralizes equipment health data, streamlines task planning, and ensures regulatory compliance, helping you increase equipment reliability and reduce costs.

CORE CAPABILITIES DRIVING YOUR SUCCESS

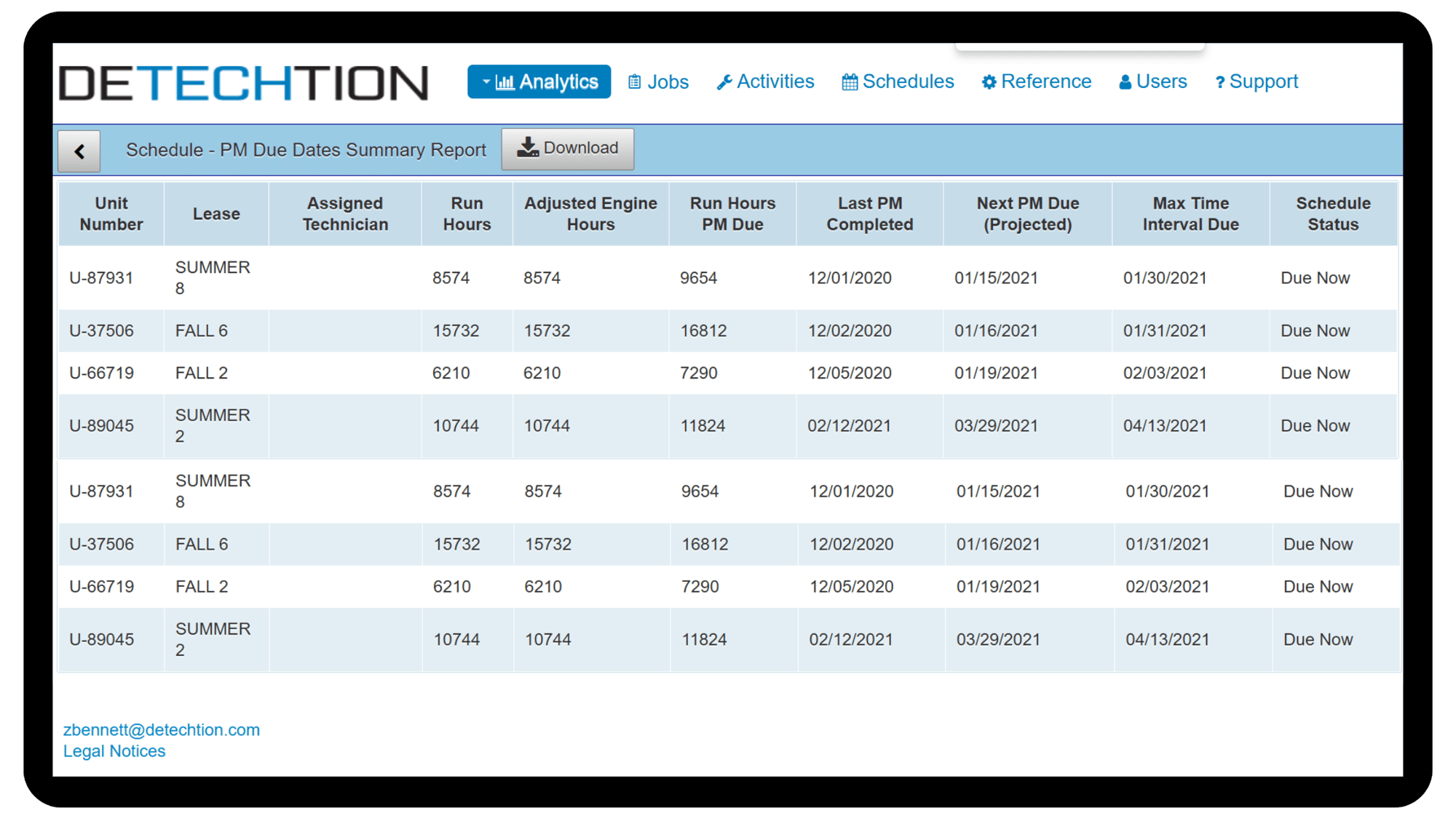

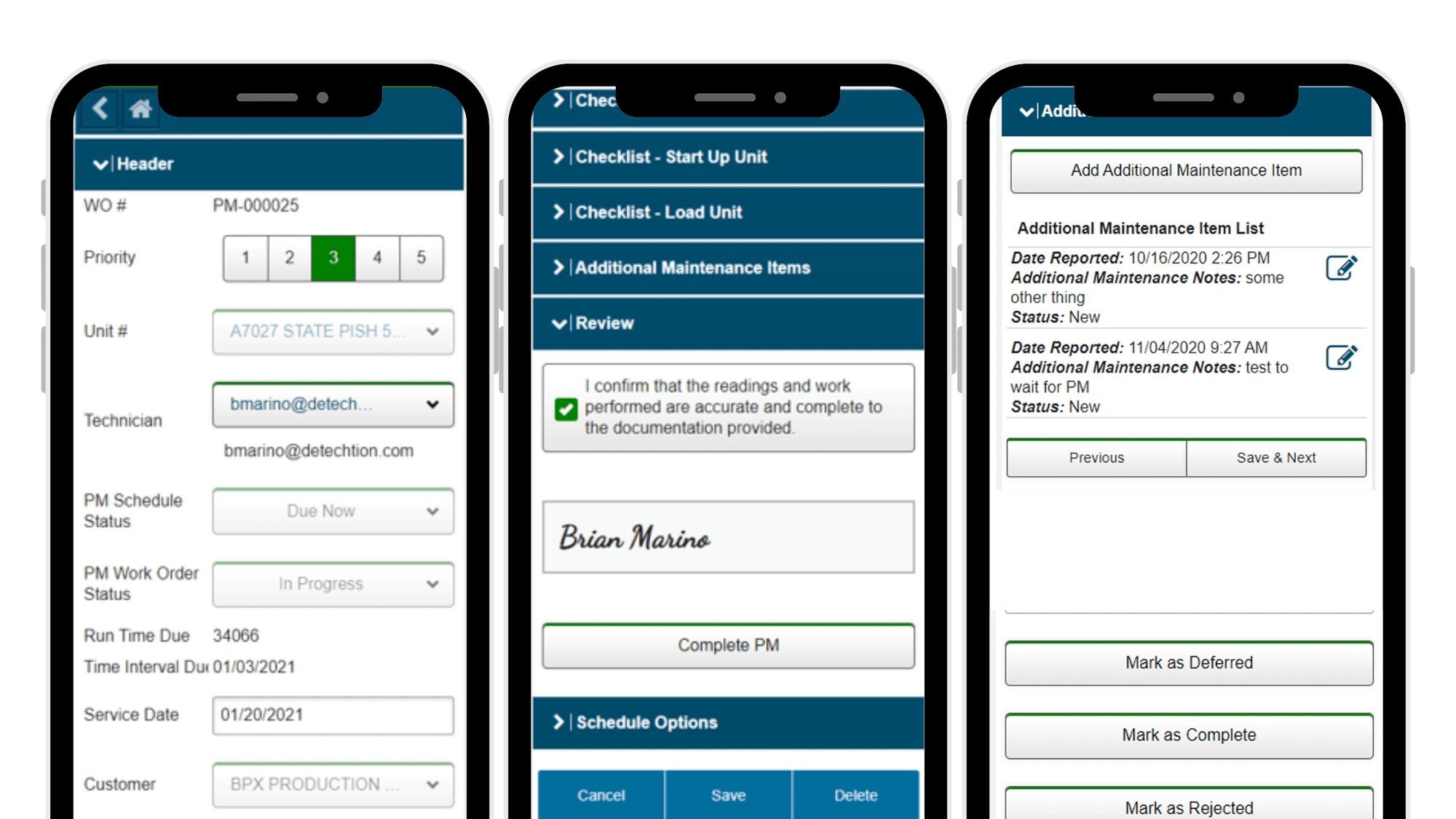

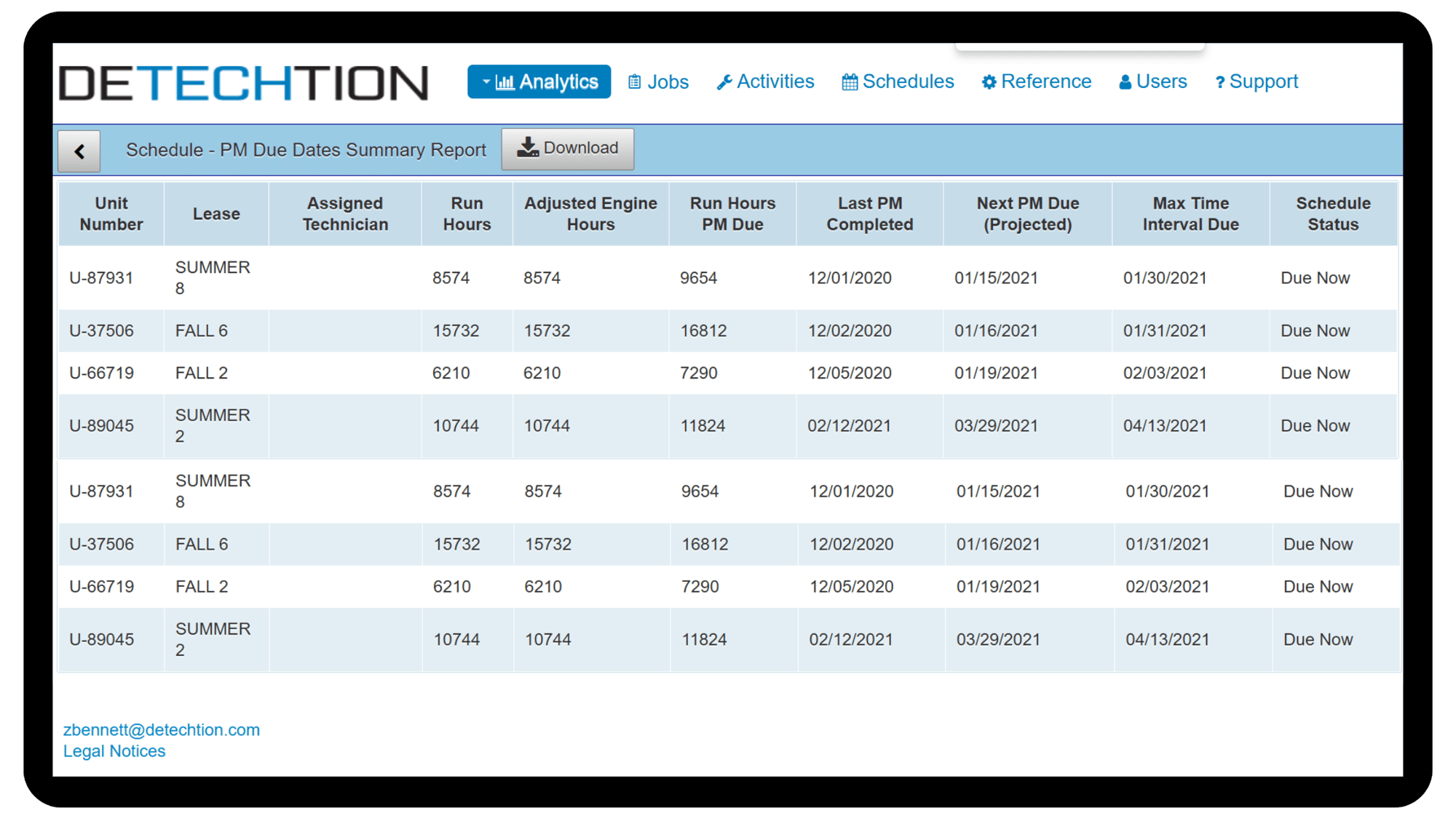

Plan maintenance tasks in advance with intelligent scheduling tools that optimize service intervals and reduce unplanned downtime.

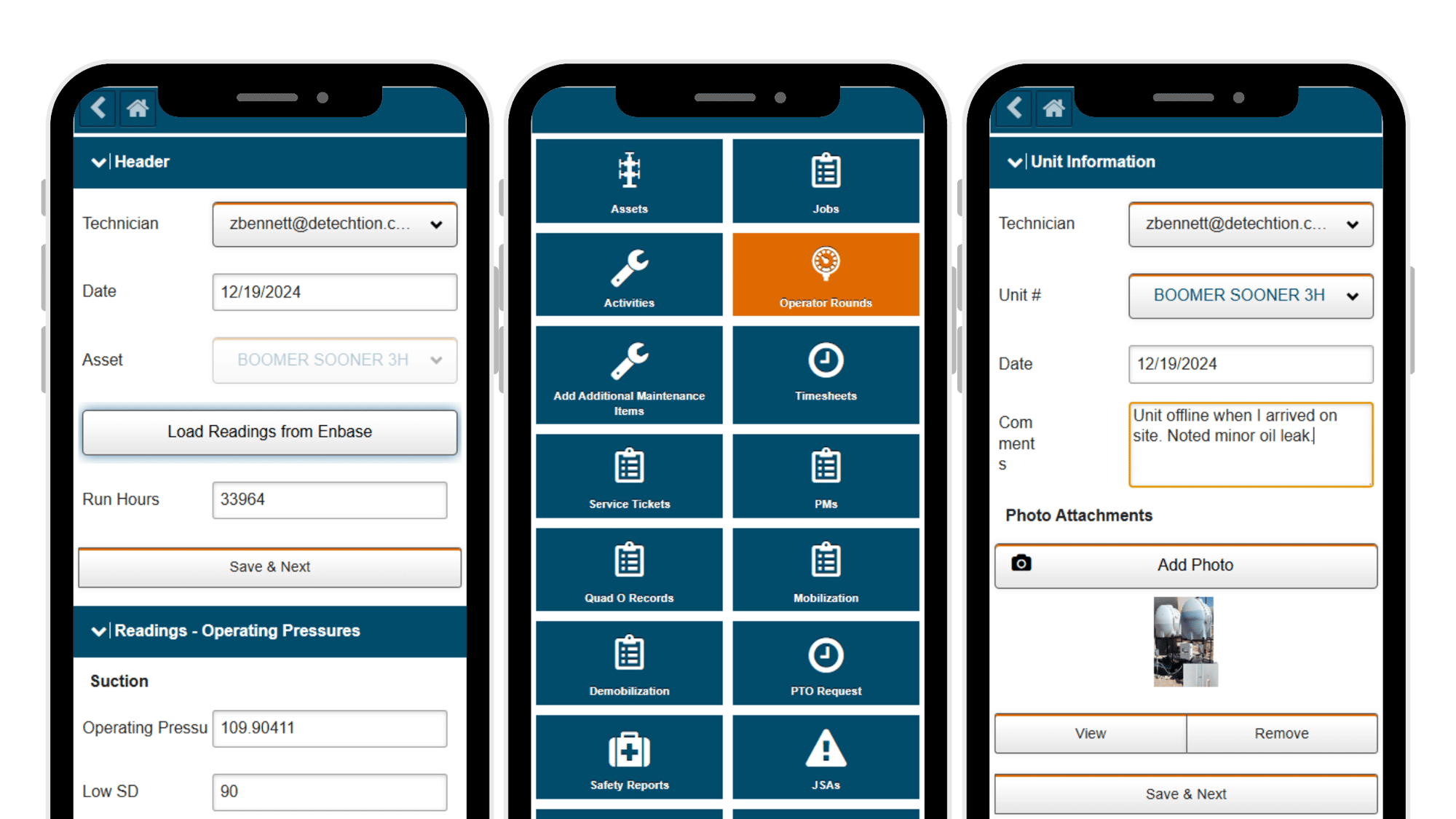

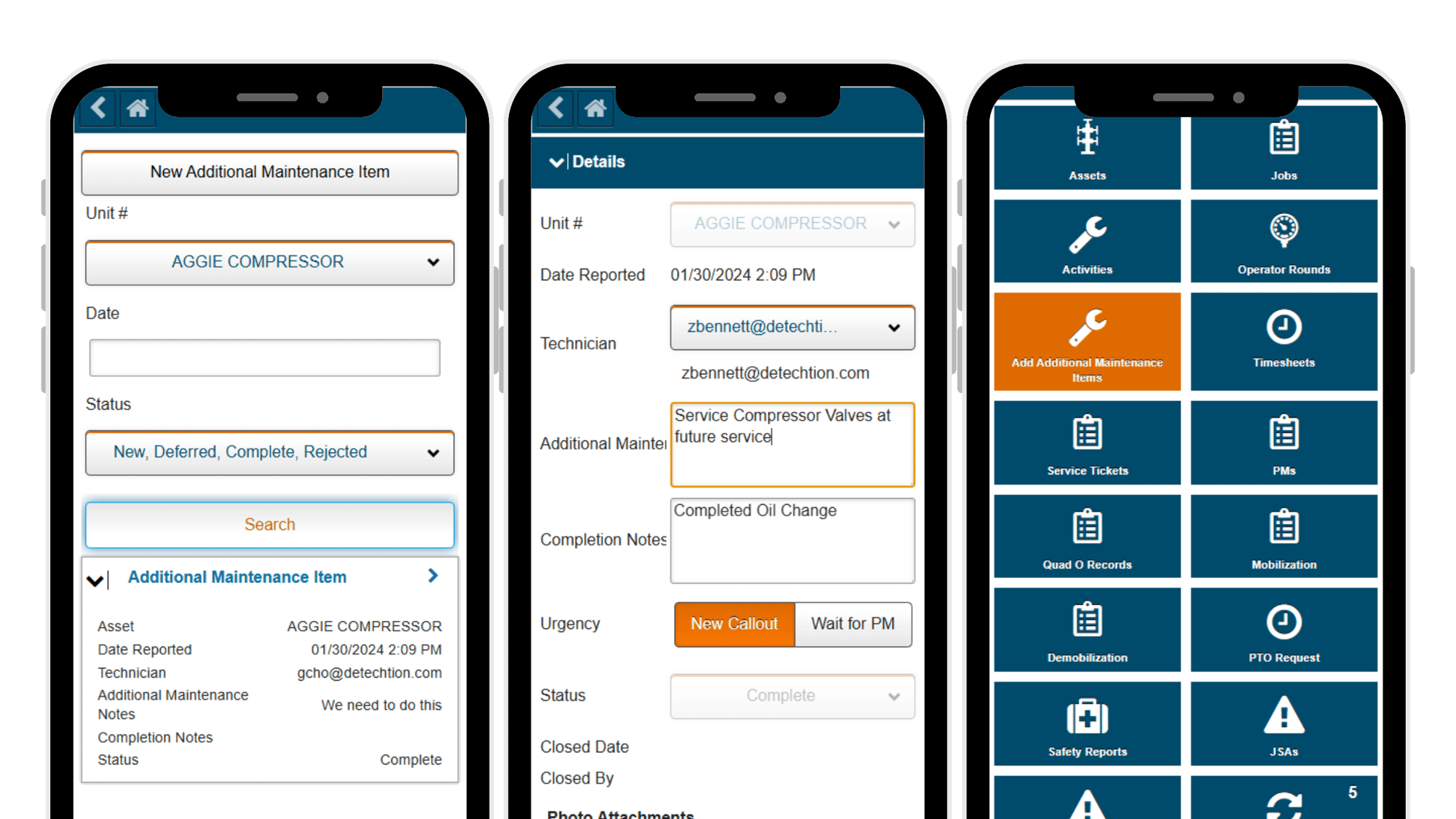

Gain actionable insights into equipment performance with real-time data, allowing teams to address potential issues before they become critical.

Consolidate maintenance records into a single platform for easy tracking, ensuring accurate documentation and streamlined audit preparation.

Automate the creation of reports to meet safety and maintenance standards, ensuring adherence to regulations with minimal manual effort.

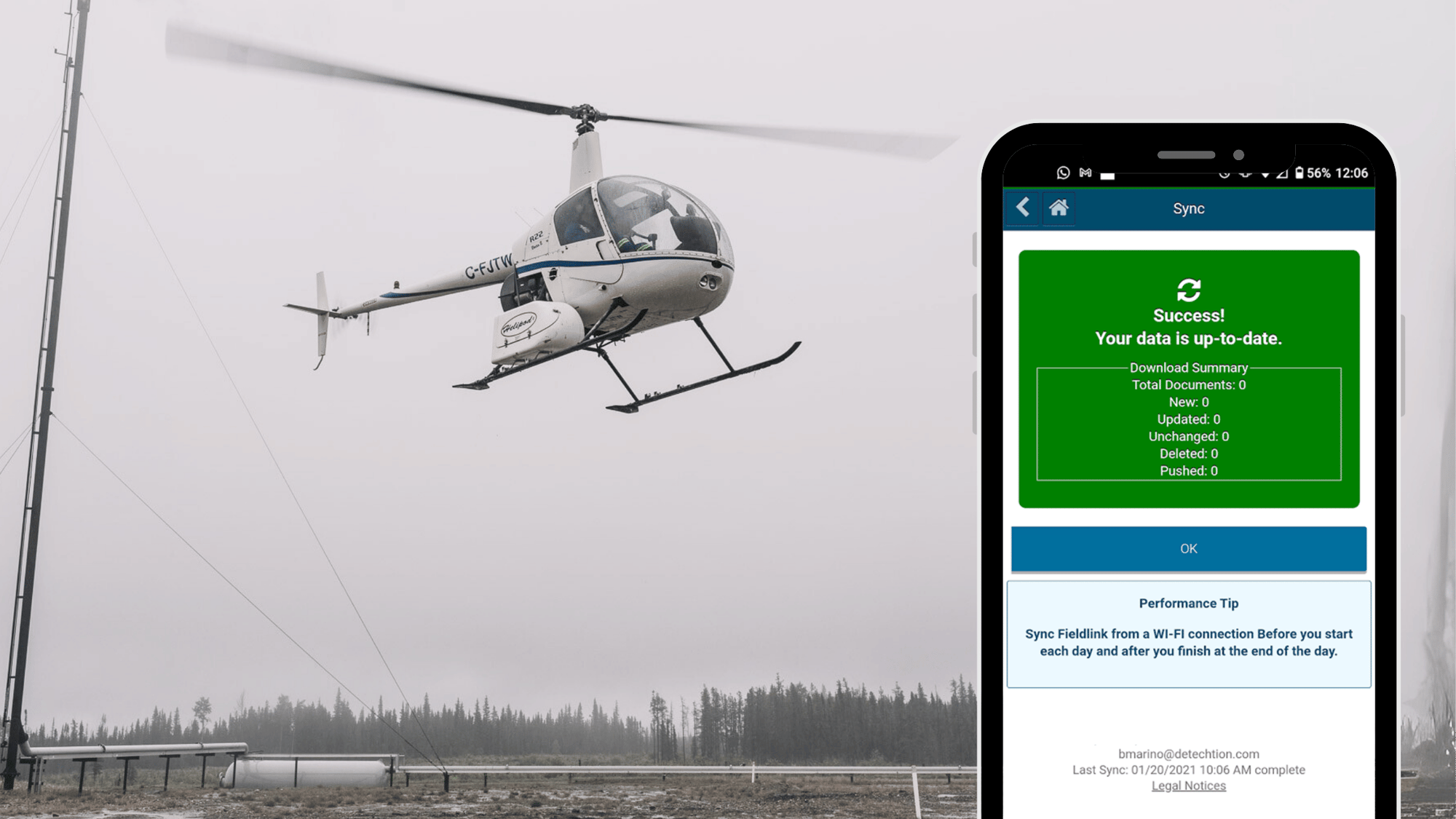

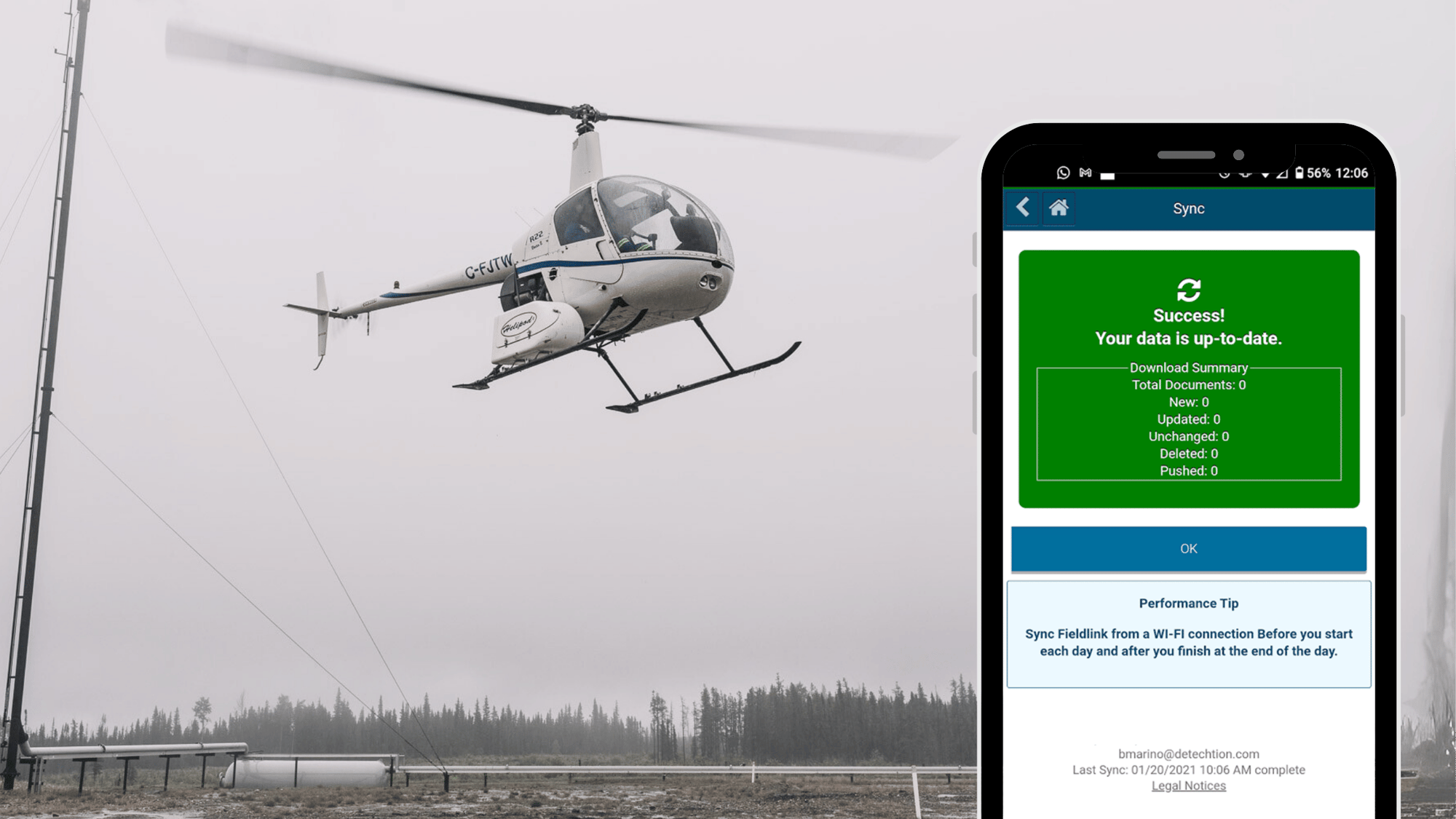

Enable teams to capture and access maintenance data from remote locations, even offline, with seamless synchronization when back online.

CORE CAPABILITIES DRIVING YOUR SUCCESS

Plan maintenance tasks in advance with intelligent scheduling tools that optimize service intervals and reduce unplanned downtime.

Gain actionable insights into equipment performance with real-time data, allowing teams to address potential issues before they become critical.

Consolidate maintenance records into a single platform for easy tracking, ensuring accurate documentation and streamlined audit preparation.

Automate the creation of reports to meet safety and maintenance standards, ensuring adherence to regulations with minimal manual effort.

Enable teams to capture and access maintenance data from remote locations, even offline, with seamless synchronization when back online.

Reduce Downtime, Lower Costs, and Improve Equipment Reliability

By moving from reactive to proactive maintenance, clients achieve:

Reduction in Production Issues

Reduction to overdue inspections

Total Fleet Visibility

Move from Reactive to Proactive Maintenance

Core solutions that help you reduce downtime, lower costs, and improve reliability.

Protect Your People, Your Profit, and the Planet

We deliver end-to-end monitoring, control, and reporting solutions for chemical tank data, simplifying chemical management. Our solutions reduce costs and environmental impact all while optimizing oilfield production, data accuracy, operational efficiency and dosage safety.

Explore our other Mobile Oilfield Management Solutions

"Even the most skeptical users have embraced FieldLink. What used to take multiple calls and manual coordination is now at our fingertips. This has not only streamlined communication but also allowed us to focus on the tasks that matter most."

Maintenance Coordinator, Major Compressor Leasing Company

FAQs

When you decide to invest in a powerful piece of technology, no matter how user-friendly it may be, you’re still bound to have questions. We’re happy to help you as you discover the capabilities of Detechtion and are here for you every step of the way.

How does Detechtion’s solution reduce unplanned downtime?

By automating maintenance schedules and monitoring equipment in real-time, it helps teams address potential issues proactively, avoiding costly breakdowns

Can the platform track maintenance history for audits?

Yes, it consolidates all maintenance records into one platform, ensuring easy access to accurate, audit-ready documentation.

Does the solution help with regulatory compliance?

Absolutely. It automates reporting and tracks maintenance tasks to ensure adherence to safety and maintenance regulations.

How does the offline functionality benefit field teams?

Teams can capture and access critical maintenance data in remote locations without connectivity, with automatic synchronization when online again.

Transform Your Maintenance Strategy Today

Ready to move from reactive to proactive maintenance? Detechtion’s Preventative Maintenance solution equips your team with the tools to reduce downtime, improve safety, and streamline compliance.

Transform Your Maintenance Strategy Today

Ready to move from reactive to proactive maintenance? Detechtion’s Preventative Maintenance solution equips your team with the tools to reduce downtime, improve safety, and streamline compliance.

Natural Gas Company Reduced Opex by 18%

Read how one of our customers drastically improved their operations with our mobile solutions.

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.

Welcome to the Future of Oilfield Efficiency

The next era of oilfield management is built on the foundation of accuracy, efficiency, and operator confidence. As an oilfield operator, you’re at the forefront of your organization’s evolution.