Houston, TX |

New commercial model enables customers to cost effectively remotely monitor oilfield assets

Houston, TX (November 17, 2020) - Detechtion Technologies, the proven Asset Performance Management, Industrial IoT, and Mobile Oilfield Management solution provider in the Upstream Oil & Gas industry, today announced the availability of its Enbase product line on a Hardware-as-a-Service basis. With the Hardware-as-a-Service subscription, customers receive the Enbase software as well as the edge device all in one simple monthly fee.

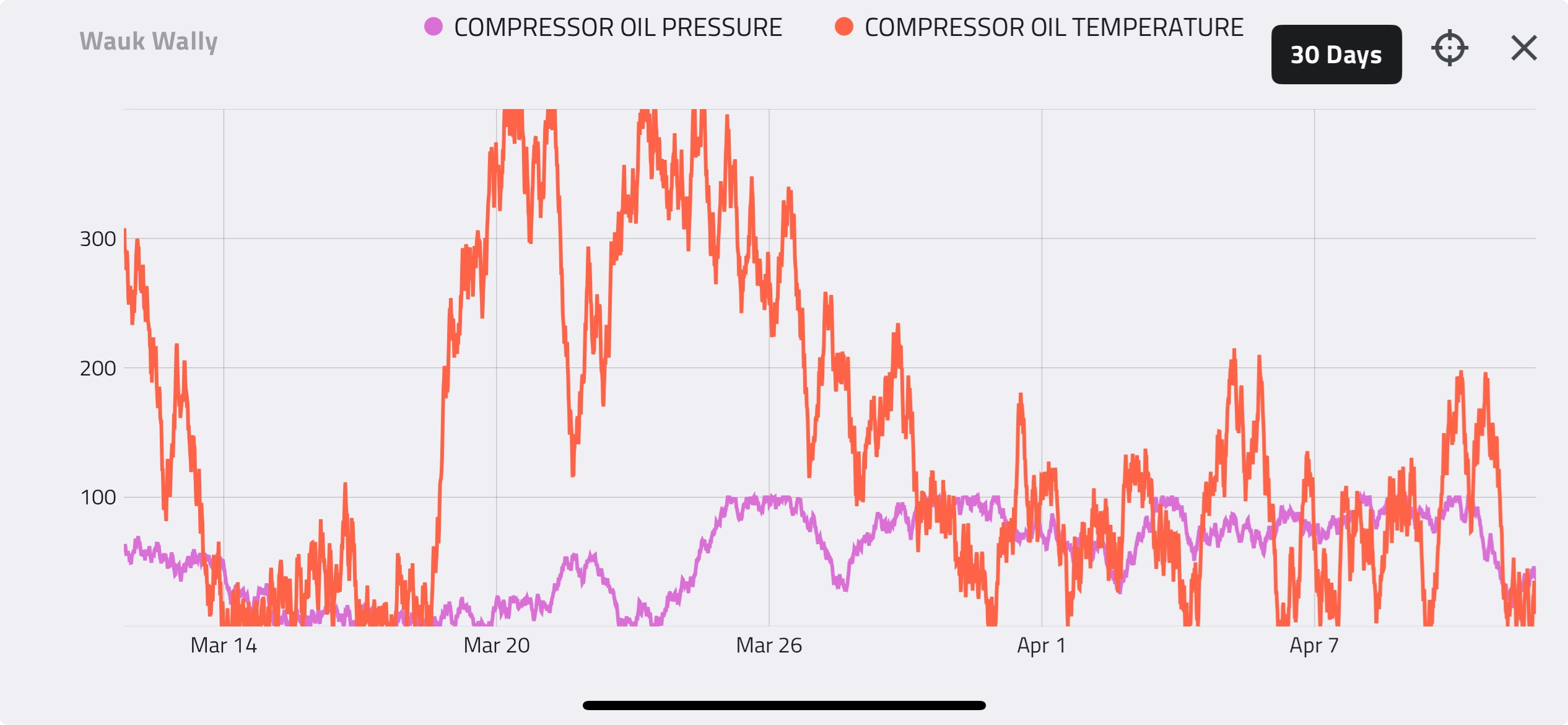

Detechtion’s Enbase Industrial IoT platform provides a turnkey solution for the Oil & Gas industry to remotely monitor oilfield assets such as natural gas compressors with a completely integrated technology stack that includes the edge device, edge software, cellular and satellite network communications, and cloud software. The Enbase Hub, Detechtion’s market leading edge device, is a key component of this solution that enables Producers and Service Companies alike to remotely monitor their oilfield assets, providing visibility to current operating conditions including alarms for critical events such as unplanned shutdowns.

“Today we live in very turbulent times dealing with the global impacts of COVID-19, including volatile demand for oil & gas that has our entire industry scrambling to operate more efficiently at reduced commodity prices,” said Kirk Hanes, Senior Vice President of Global Sales at Detechtion. “Detechtion’s new Enbase Hardware-as-a-Service offering provides a way for our customers to digitally transform their operations to reduce their operating costs. It greatly reduces the time it takes to get critical data from their oilfield assets into their hands allowing them to make better, more timely decisions that impact their business.”

A key benefit of this transparency is saving unnecessary trips to site. Customers can operate by exception and only send personnel to site when needed. When a trip is required, customers are armed with more complete information and insight to ensure they are sending the right person with the right tools and parts for the job at the right time.

“Having already tested this model with several of our key customers on 1000s of oilfield assets,” Hanes continued, “we felt the time was right to expand this program and make it available to our broader customer base. Due to economic pressures, we are seeing a lot of companies postpone capital expenses and look for operational solutions and Hardware-as-a-Service fits that need.”

The Enbase Tank Level Sensor (TLS) will also be available on a Hardware-as-a-Service basis. The Enbase TLS can be used to monitor continuous chemical injection tanks, which are key to ensuring optimum production as well as protecting the well, equipment and piping from damage and leaks. It arms Operators and Chemical Providers with critical information including the current tank level, the number of days until the tank will be empty, and chemical injection rates. It can also alert on no-flow situations such as when the pump is vapor locked.