Unlock Your Fleet’s Potential.

The leading compressor asset management software solution designed specifically for oil and gas operations. Enalysis optimizes reciprocating and rotary screw compressor performance, leveraging cutting-edge digital twin technology to align assets with real-time operating conditions. It delivers unparalleled insights to ensure your compressor fleets consistently operate at peak performance in the challenging oil and gas environment.

Unlock Your Fleet’s Potential

The leading compressor asset management software solution designed to optimize reciprocating and rotary screw compressor performance, Enalysis leverages cutting-edge digital twin technology to align assets with real-time operating conditions, deliver unparalleled insights and ensure your compressor fleets always operates at peak efficiency.

Enalysis Eliminates Guesswork

Our predictive technology minimizes downtime, extends equipment lifespan, and decreases maintenance costs, critical for maximizing oil and gas operations' uptime.

Digital Twin Technology

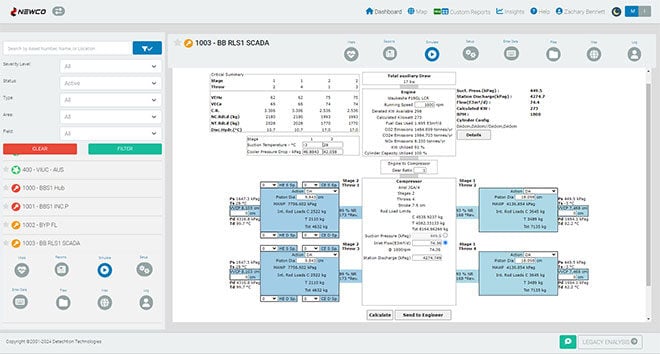

Enalysis employs digital twin technology to create a virtual replica of your oil and gas assets and systems, using real-time data to simulate, predict, and optimize performance and behavior, ensuring operational reliability.

Simulation-Driven Accuracy

Our innovative simulation approach enables you to make data-driven decisions, foresee potential issues, and implement improvements before they impact oil and gas production.

Increase utilization throughput up to 2% for compressor fleets critical to oil and gas processes.

Effortlessly apply learnings across all compressors in your oilfield operations.

Reduce power consumption by up to 4%, supporting sustainability goals while maintaining production levels.

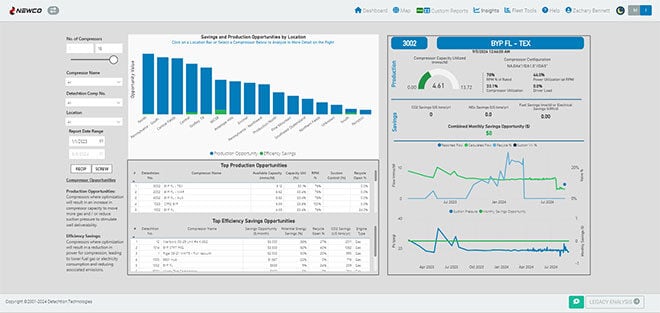

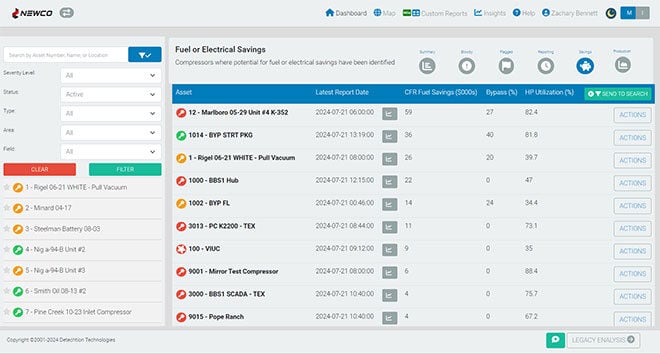

Optimization

Enalysis’ simulation tools evaluate the best configurations for oil and gas compressors and identify improvement opportunities with clear performance indicators.

Get The Most out of your Compressor

Whether adjusting control set points, modifying configurations, or analyzing your setup, Enalysis ensures that compressors critical to oil and gas operations are running at peak efficiency, reducing energy consumption and increasing throughput.

- Data-Driven: Integrates data from Enbase Hub, SCADA, or manual inputs for precise analysis

- Actionable Metrics: Quickly identify production and fuel-saving opportunities with clear metrics

- Simulation-Guided: Uses simulation to optimize compressor configurations for maximum efficiency

- Real-Time Monitoring: Monitors performance in real-time to maintain peak efficiency

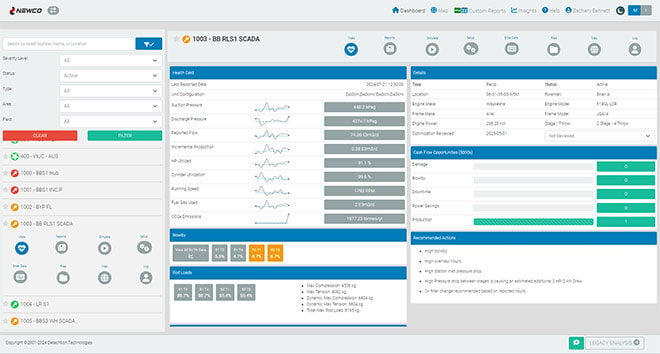

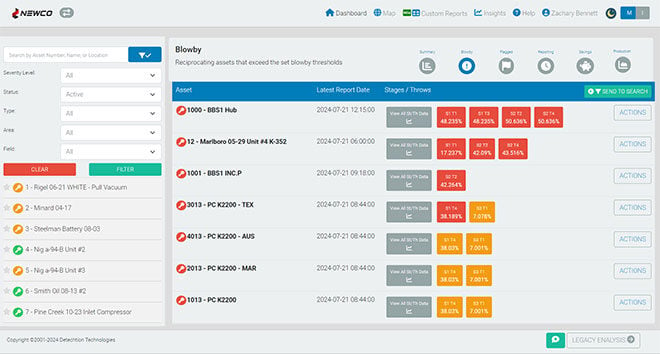

Failure Prevention

From evaluating optimized configurations to identifying maintenance needs, Enalysis monitors compressor health in oil and gas operations and analyzes performance data to predict failures and recommend proactive solutions.

Reliability Centered Maintenance

Optimize compressor configurations and set points to prevent issues in the demanding oil and gas environment. The result? Less downtime, extended equipment lifespan, and lower maintenance costs.

- Predictive Monitoring: Continuously tracks compressor health and performance in real-time

- Proactive Solutions: Leverages digital twin modeling to evaluate optimized configurations

- Instant Alerts: Provides real-time notifications when KPIs deviate from normal

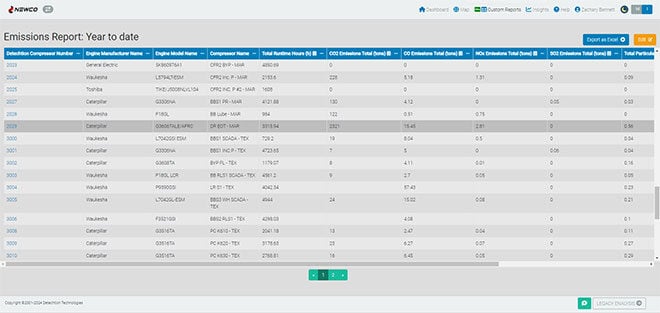

Emissions Management

Enalysis ensures compliance with oil and gas regulations while supporting sustainability initiatives with real-time monitoring and accurate emissions data calculations.

Prioritize the Planet (& Your Business Initiatives)

Gain emissions transparency with standardized templates and customizable reporting options to track, manage, and reduce environmental impact across oil and gas operations.

- Tracks fuel composition, runtime, and engine performance to provide insights into greenhouse gas emissions (CO2, CO2e, NOx, CO)

- Offers built-in support for MSAPR and Directive 60 for seamless regulatory compliance in oil and gas fields

- Elevates Enalysis' capabilities with Fieldlink’s tailored inspection forms for your organization’s needs

Never Be Caught Off-Guard Again

Enalysis effortlessly aligns your current procedures with your future goals. Ready to reduce downtime and emissions while increasing utilization?

Never Be Caught Off-Guard Again

Enalysis effortlessly aligns your current procedures with your future goals. Ready to reduce downtime and emissions while increasing utilization?

From 84% to 91.5% Utilization: Optimizing Fleet Efficiency for Higher Throughput

See how one company realized a continuous improvement in compressor fleet performance over the last four years and a total, fleet-wide performance improvement of more than 7.5%.

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.

Contact Us

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euis