Control & Autonomy for Compressors

Maximize Performance, Minimize Downtime

Control and autonomy solutions by Detechtion empower you to dynamically optimize compressor operations in real time. By combining advanced edge-based intelligence with seamless integration and remote capabilities, you can ensure safe, efficient, and reliable performance across your fleet—no matter the conditions.

Are You Getting the Most from Your Compressors?

What if you could prevent shutdowns, increase runtime, and unlock the full potential of your compressor fleet without costly interventions or on-site adjustments?

Welcome to the Future of Oilfield Efficiency

The next era of oilfield management is built on the foundation of accuracy, efficiency, and operator confidence. As an oilfield operator, you’re at the forefront of your organization’s evolution.

The Detechtion Advantage

The Detechtion Advantage

Proven Results for Your Fleet

Unlock Tangible Business Value

Runtime

Prevented Shutdowns

Consolidated and Future Proof System

What Sets Us Apart

Key functionalities to meet changing operational needs

"We were looking for top-notch technology and the best customer service. After evaluating various companies, we found that Detechtion was the one capable of delivering both, which is why we decided to go with them."

Eloy Renteria

Service Manager with Longfellow Energy

Frequently Asked Questions

Can I use Detechtion’s solutions with my existing compressor skids?

Yes. Our control solutions are hardware-agnostic and designed to integrate seamlessly with most compressor systems. Whether your equipment is new or legacy, our system works across a variety of engine controllers, including Waukesha ESM/ESM2, CAT ADEM 3/4 and other industry-leading platforms.

What is the ROI of using your control system?

For operators that don't already have PID Control, operators typically see a 1–2% increase in runtime, reduced maintenance costs and fewer shutdowns, translating to significant cost savings and production gains.

Can I monitor and adjust compressors remotely?

Yes. With secure, real-time remote access, you can:

✅ Monitor performance with cloud-based dashboards

✅ Adjust setpoints instantly to optimize efficiency

✅ Start or stop operations from anywhere with mobile and desktop control

Our SOC2 Type 2-compliant infrastructure ensures secure data handling and remote access.

What happens if my compressor is in a location with no cellular coverage?

Cellular communication is the default option. However, our solutions leverage multiple connectivity options, including satellite communication, to ensure remote monitoring and control even in the most remote oilfield environments.

How does your system handle callouts and escalation?

Detechtion provides a structured callout and escalation process, ensuring the right personnel are notified based on priority levels. This minimizes response time and helps prevent extended downtime by escalating alerts until action is taken.

What makes the control and autonomy solution by Detechtion different?

✔ Edge-based intelligence ensures real-time decision-making at the source

✔ Remote-first capabilities allow operators to manage compressors from anywhere

✔ Seamless integration with legacy and modern control systems

✔ Automated downtime management improves uptime and operational efficiency

✔ Unmatched expertise in compression, automation, and engine management

Ready to Optimize Your Compressor Operations?

Maximize uptime, reduce costly shutdowns, and take control of your fleet with Detechtion’s advanced control and autonomy solutions.

Ready to Optimize Your Compressor Operations?

Maximize uptime, reduce costly shutdowns, and take control of your fleet with Detechtion’s advanced control and autonomy solutions.

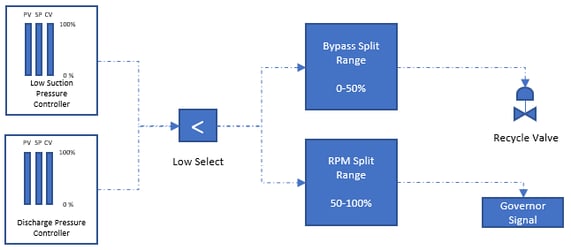

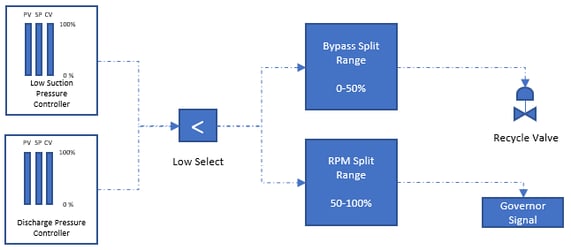

Detechtion Control System Resulted in $45,000/Month Benefit

By leveraging advanced PID Control Strategies, an operator was able to significantly increase uptime and utilization.

Longfellow Energy Upgrades to the Detechtion Compressor Control Panel

"We were looking for top-notch technology and the best customer service." Eloy Renteria, Service Manager