Dynamic Package Control

Unlock $150K of Hidden Value per Compressor

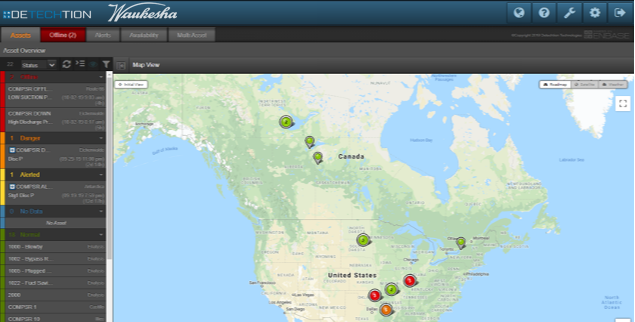

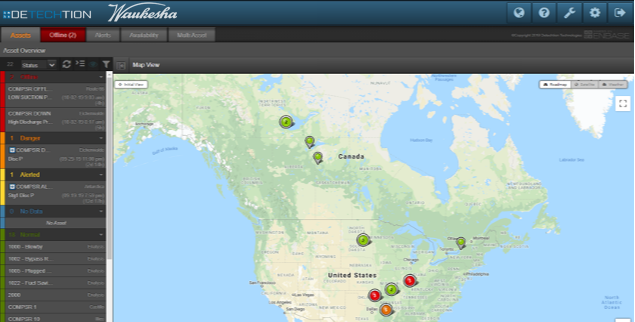

Most compressors are leaving money on the table - Dynamic Package Control helps you recover it. By dynamically adjusting control parameters in real time, our advanced edge-based digital twin ensures higher runtime, fewer shutdowns, and optimized production. With seamless remote integration, you can manage your fleet effortlessly while increasing efficiency and reducing costs. Powered by SkidIQ Adapt, this solution continuously optimizes compression parameters, maximizing throughput while minimizing unplanned downtime.

Are You Limiting Your Compressor’s Potential?

What if your compressors could dynamically adjust to changing field conditions, automatically increasing runtime, reducing failures, and optimizing performance—without on-site tuning?

Welcome to the Future of Oilfield Efficiency

The next era of oilfield management is built on the foundation of accuracy, efficiency, and operator confidence. As an oilfield operator, you’re at the forefront of your organization’s evolution.

The Dynamic Package Control Advantage

Proven Results for Your Fleet

Unlock Tangible Business Value

Runtime Increase

Fewer Onsite Callouts

Utilization Increase

Consolidated Package Control System

What Sets Dynamic Package Control Apart

Key functionalities to meet changing operational needs

"With Dynamic Package Control, we've significantly reduced shutdowns and maximized uptime without manual intervention. It has transformed how we manage our compressor fleet."

Production Foreman

Upstream Producer

Frequently Asked Questions

Can I use Dynamic Package Control with my existing compressor skids?

Dynamic Package Control will work with all reciprocating compressors makes/models and has a two-year exclusivity for Waukesha Engine. It has been designed to work with any compressor and engine combination, so following the period of exclusivity, it will work for all engine and reciprocating compressor combinations.

What is Dynamic Package Control (SkidIQ Adapt)

SkidIQ Adapt is a patented solution developed collaboratively by Detechtion and Waukesha Engine. It uses real-time data and digital twin technology to optimize compressor package performance, reducing downtime, increasing utilization, and lowering operating costs.

How does Dynamic Package Control differ from traditional systems?

Traditional systems uses static setpoints based on limited set of process variables for compressor control. SkidIQ Adapt uses real-time measured and calculated variables (e.g., rod loads, volumetric efficiencies) for dynamic adjustments, allowing compressors to operate within a wider and safer range.

How does SkidIQ Adapt reduce downtime?

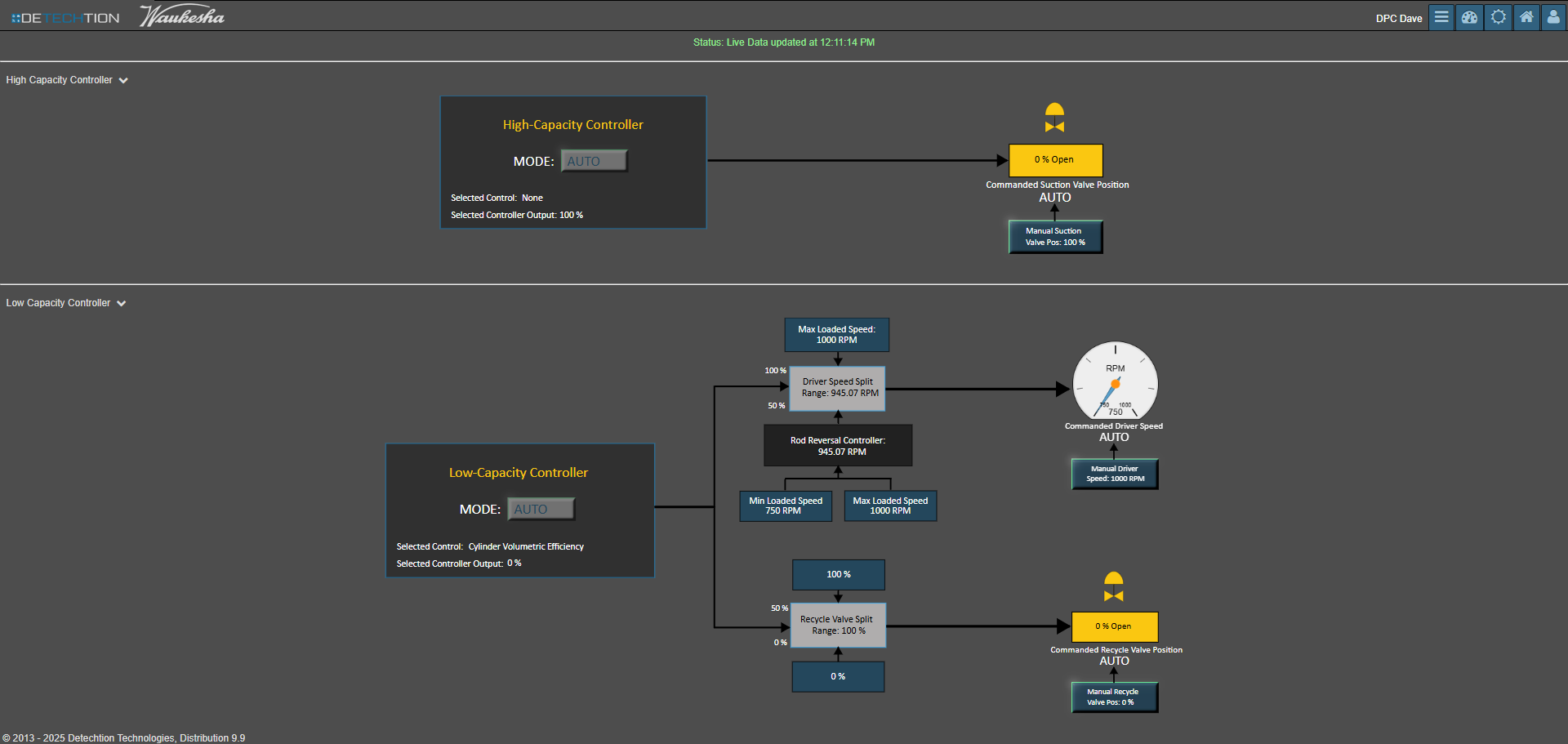

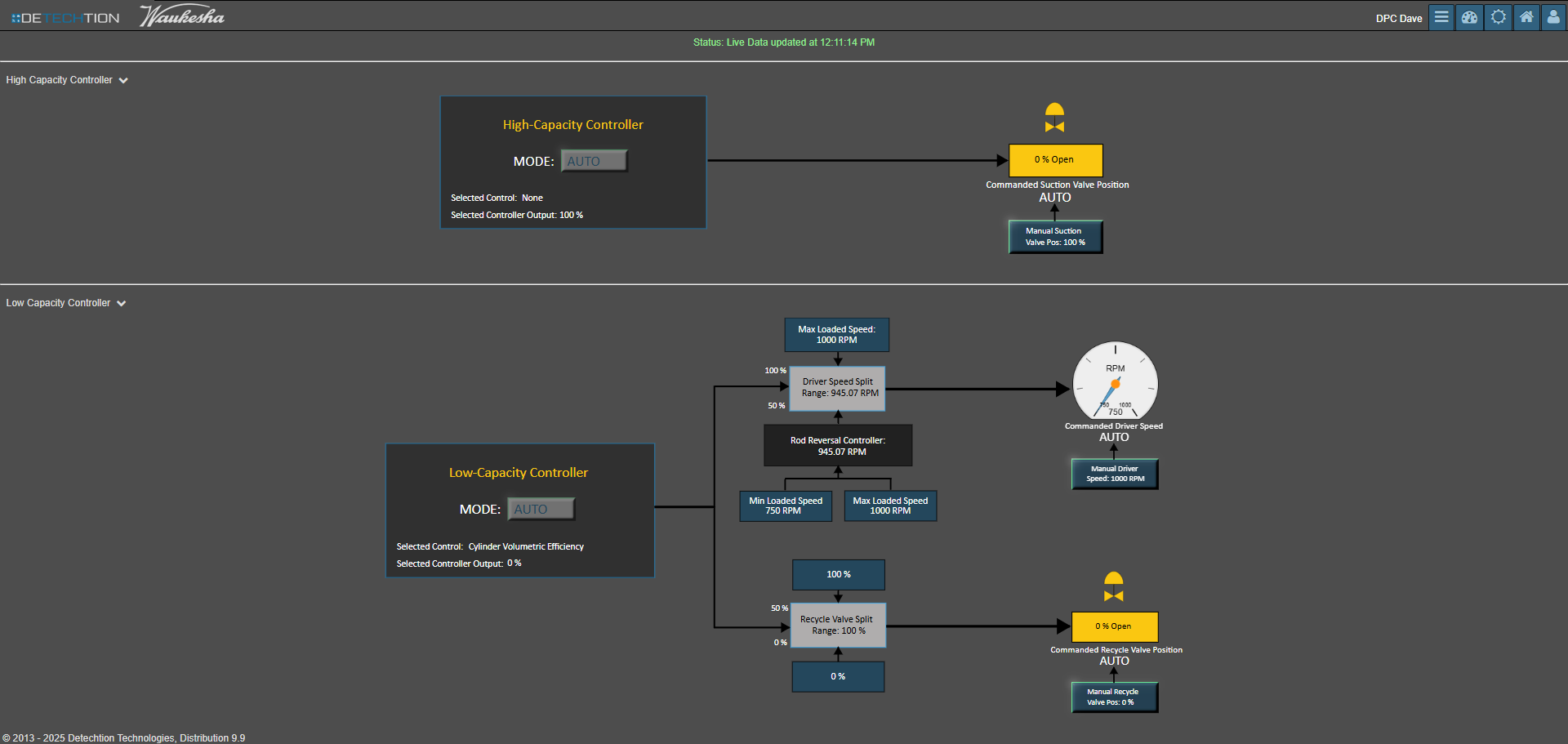

It continuously monitors critical variables and dynamically adjusts driver speed, suction valve, and recycle valve positions to prevent shutdowns during low-capacity conditions, keeping compressors running in fluctuating field conditions.

What are the high-capacity and low-capacity responses?

High-Capacity Response adjusts suction control when variables such as driver load, engine IMAT, or rod loads exceed their set point range. Low-Capacity Response adjusts speed and activates bypass valves to prevent shutdowns during low gas volumes when variables such as low volumetric efficiencies or low suction pressures exceed their set points.

How does SkidIQ Adapt improve utilization?

By responding to real-time performance data, SkidIQ Adapt operates compressors at optimal capacity, maximizing production and minimizing unnecessary shutdowns while extending the safe operating range.

How does SkidIQ Adapt contribute to emissions reduction?

SkidIQ Adapt optimizes compressor operations during periods of low gas volumes, reducing fuel consumption and emissions. It ensures compressors run more efficiently and minimizes flaring or venting, helping operators meet environmental regulations.

Can Dynamic Package Control integrate with existing systems?

Yes. Depending on the make and model of your existing control system, SkidIQ adapt will either replace your existing control system entirely, or can be implemented as "Shared Control." In the shared control, your existing controller may continue to perform transient control (start/stop) while SkidIQ Adapt performs steady-state control.

Detechtion will advise on the solution throughout the discovery process.

What are the requirements for SkidIQ Adapt?

Reciprocating Compressor, Waukesha Engine, Actuated Suction Control Valve and Bypass Control Valve.

How is the digital twin used in SkidIQ Adapt?

The digital twin models real-time compressor performance, calculating metrics like rod loads, cylinder blowby and volumetric efficiencies, which are used within the control logic and serve as useful analytics for operations teams to further optimize performance of equipment, and identify preventative maintenance opportunities.

Ready to Optimize Your Compressor Operations?

Maximize uptime, prevent unnecessary shutdowns, and take control of your fleet with Detechtion’s Dynamic Package Control.

Ready to Optimize Your Compressor Operations?

Maximize uptime, prevent unnecessary shutdowns, and take control of your fleet with Detechtion’s Dynamic Package Control.

Detechtion Control System Resulted in $45,000/Month Benefit

By leveraging advanced PID Control Strategies, an operator was able to significantly increase uptime and utilization.

Waukesha Engine and Detechtion Announce Alliance

To deliver Next-Level Engine and Compressor Monitoring and Optimization Capabilities