Any Asset, Any Time, Anywhere.

You can’t be everywhere at once. But the Enbase Suite of Products can. Specifically designed for oil and gas operations, Enbase monitors, controls, protects, and optimizes remote compression and chemical equipment. As the most trusted IIoT technology in the digital oilfield, Enbase empowers operators with unparalleled visibility and control.

Defining a New Data Paradigm

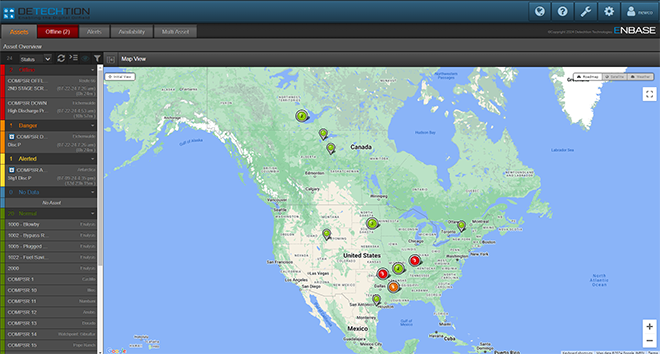

Enbase captures real-time data to monitor and optimize compression and chemical dosing, syncing insights to a cloud-based dashboard and automating actions for remote and hard-to-reach oil and gas production units.

The Power of Computing at the Edge

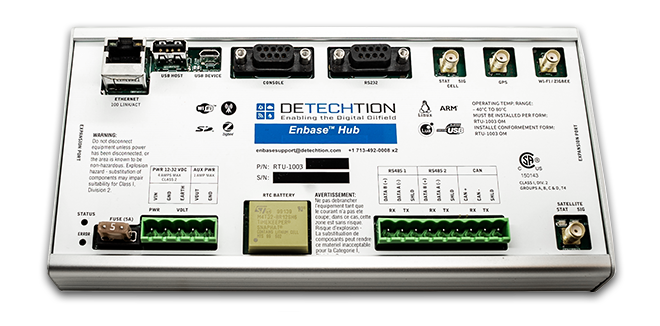

The Enbase Hub brings computing directly to the compressor skid. Edge computing provides significant efficiency, responsiveness, and data security advantages, offering flexibility to optimize performance with advanced control techniques like override and split-range PID control.

One Solution, All Your Assets

Enbase’s manufacturer-agnostic design supports compressor modeling and control, backed by experts in compression, automation, and software. By merging world-class IoT hardware and software, Enbase transforms raw data into actionable insights for oil and gas operators.

Maximize productivity with data-driven insights and operational visibility.

Avoid costly shutdowns with automation and remote control capabilities.

Improve trip planning with accessible data and streamlined callout management.

Five Cutting-Edge Solutions, One Formidable Data Foundation

The Enbase line of products is purpose-built to monitor, control, and optimize compressor fleets with precision for the oil and gas industry.

Enbase Hub

The Enbase Hub integrates seamlessly with existing controllers, annunciators, and pyrometers, relaying critical information through the Enbase Dashboard.

Total Data Visibility

Customizable alarms, acknowledgments, and elevation paths (email, text, and web) indicate whether a call-out is required, while edge computing optimizes parameters like pressure, temperature, and flow.

- Install Anywhere: Built-in remote communication via cellular and satellite.

- Edge Computing: Advanced monitoring and control for an unlimited range of parameters.

- Secure: Enterprise-grade security with two-factor authentication.

- Universal Connectivity: Connects to nearly any Modbus system, including Caterpillar ADEM III/IV, Waukesha ESM/ESM2, and Murphy EICS.

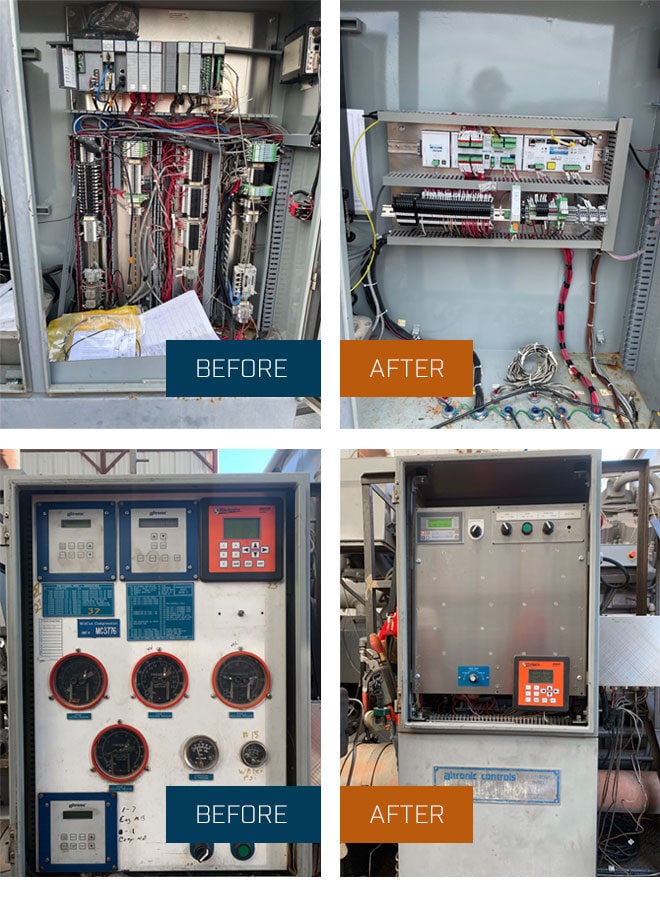

Enbase Compressor Control Panel

Powered by Enbase Hub, this control panel is available as a retrofit for existing panels or as a new installation. It provides fleetwide automation for oil and gas operators.

Adaptive Control from Anywhere

Capitalize on real-time data insights to extend operating ranges, remotely stop assets, and optimize compressor operations for efficiency, security, and responsiveness.

- Edge Computing: Leverage real-time analytics for precise control of operating parameters.

- Flexible Configuration: Adapt control settings to meet operational needs.

- Scalable and Secure: Features over-the-air updates, enterprise-grade security, and seamless scalability.

Enbase Asset Monitor

This rugged, battery-operated IoT device monitors remote assets, providing real-time location and run status updates via vibration sensing.

Effortlessly Track and Locate Assets

Monitor asset performance and run status in real time, ensuring operational visibility for remote oilfield equipment.

- Vintage-Friendly: Compatible with any equipment generating consistent vibration.

- Long-Lasting: Rugged design with a 10-year battery life.

- Cloud-Enabled: Includes a secure cloud application for trend analysis and reporting.

- Easily Located: GPS-enabled for precise equipment tracking.

Explore our other Technologies

Unlock Your Fleet’s Potential.

Unify, Optimize, and Empower Your Oilfield Operations

Unlock $150K in hidden value per compressor.

Know More and Achieve More with Enbase

The Enbase Suite combines computing at the edge and universal connectivity to unlock your compressor fleet's (and your team's) full potential. Ready to make educated decisions faster?

Know More and Achieve More with Enbase

The Enbase Suite combines computing at the edge and universal connectivity to unlock your compressor fleet's (and your team's) full potential. Ready to make educated decisions faster?

Longfellow Energy Upgrades to the Detechtion Compressor Control Panel

Learn how one client integrated a modern panel that would consolidate all monitoring and control systems into one seamless platform.

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.

Five Cutting-Edge Solutions, One Formidable Data Foundation

Management

Total Data Visibility

- Install Anywhere: Features built-in remote communications through cellular and satellite

Edge Computing: Enables advanced monitoring and control, such as split range PID control on an unlimited amount of parameters

Secure: Two-factor authentication to ensure only authorized users can access critical information - Universal Connectivity: Connect to nearly any Modbus system, including Caterpillar ADEM III/IV, Waukesha ESM/ESM2, Murphy EICS, etc

Adaptive Control from Anywhere

Powered by Enbase Hub, the Enbase Control Panel is available as a retrofit within your existing panel or as a new panel installation. This versatile technology powers a comprehensive, fleetwide approach to automation. Allows users to capitalize on real-time data insights, enabling operators to extend the operating range of their assets, remotely stop assets from anywhere, and optimize compressor utilization to ensure efficient, responsive and secure control of compressor operations.

- Edge Computing: Leverage real-time performance analytics for precise control of operating parameters

- Flexible Configuration: Allow easy adaptation of control settings to current operational needs

- Scalable and Secure: Enables over-the-air (OTA) updates, enterprise-grade security and seamless scalability across your fleet

Effortlessly Track and Locate Assets

A battery-operated, durable, and satellite-connected IoT device designed for remote monitoring of hard-to-reach assets, the Enbase Asset Monitor provides real-time location and run status updates by sensing equipment vibration. Offering robust call-out functionality and comprehensive availability reporting, the asset monitor reports all insights directly to the Enbase Dashboard.

- Vintage-Friendly: Works with any equipment that generates consistent vibration

- Long-Lasting: Durable, rugged device with a 10-year battery life

- Cloud-Enabled: Secure cloud application included for powerful trend analysis and reporting

- Easily Located: Built to move with equipment and locate with ease using built-in GPS

Measurements From Anywhere

The Enbase Tank Level Sensor enables operators to remotely monitor oil and gas chemical systems. Wirelessly collecting and exporting data to the Enbase Dashboard through a satellite connection, this sensor mounts easily on existing chemical tanks through its hydrostatic pressure transducer – allowing remote access to hyper-accurate measurements and readings.

Streamlining Chemical Due Diligence

Management

Total Data Visibility

- Install Anywhere: Features built-in remote communications through cellular and satellite

Edge Computing: Enables advanced monitoring and control, such as split range PID control on an unlimited amount of parameters

Secure: Two-factor authentication to ensure only authorized users can access critical information - Universal Connectivity: Connect to nearly any Modbus system, including Caterpillar ADEM III/IV, Waukesha ESM/ESM2, Murphy EICS, etc

Adaptive Control from Anywhere

Powered by Enbase Hub, the Enbase Control Panel is available as a retrofit within your existing panel or as a new panel installation. This versatile technology powers a comprehensive, fleetwide approach to automation. Allows users to capitalize on real-time data insights, enabling operators to extend the operating range of their assets, remotely stop assets from anywhere, and optimize compressor utilization to ensure efficient, responsive and secure control of compressor operations.

- Edge Computing: Leverage real-time performance analytics for precise control of operating parameters

- Flexible Configuration: Allow easy adaptation of control settings to current operational needs

- Scalable and Secure: Enables over-the-air (OTA) updates, enterprise-grade security and seamless scalability across your fleet

Effortlessly Track and Locate Assets

A battery-operated, durable, and satellite-connected IoT device designed for remote monitoring of hard-to-reach assets, the Enbase Asset Monitor provides real-time location and run status updates by sensing equipment vibration. Offering robust call-out functionality and comprehensive availability reporting, the asset monitor reports all insights directly to the Enbase Dashboard.

- Vintage-Friendly: Works with any equipment that generates consistent vibration

- Long-Lasting: Durable, rugged device with a 10-year battery life

- Cloud-Enabled: Secure cloud application included for powerful trend analysis and reporting

- Easily Located: Built to move with equipment and locate with ease using built-in GPS

Measurements From Anywhere

The Enbase Tank Level Sensor enables operators to remotely monitor oil and gas chemical systems. Wirelessly collecting and exporting data to the Enbase Dashboard through a satellite connection, this sensor mounts easily on existing chemical tanks through its hydrostatic pressure transducer – allowing remote access to hyper-accurate measurements and readings.