Optimize Your Fleet, eliminate unwanted shutdowns, all while unlocking $150K in hidden value per compressor.

Detechtion Technologies and INNIO Waukesha Engine have developed the SkidIQ Gas Compression product suite, a cloud-based digital solution to help operators improve efficiency, reduce callouts by 50%, reduce emissions and operating expenses.

Combining cloud-based monitoring while expanding asset connectivity.

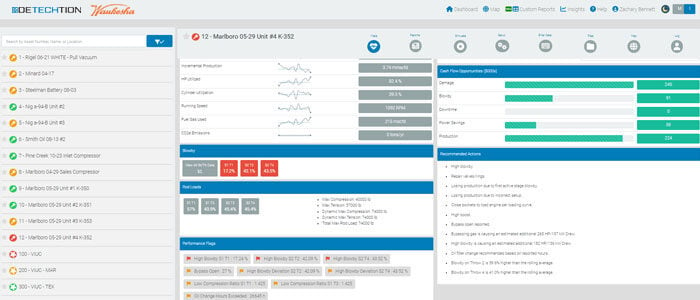

SkidIQ is an intelligent, cloud-connected platform that transforms the way operators monitor and manage compressor skids. By integrating real-time performance data with advanced analytics, SkidIQ ensures compressors operate at peak utilization while minimizing downtime. With automated control adjustments and remote access, operators can proactively optimize operations, reduce fuel consumption, and extend equipment life.

Reduce unplanned shutdowns with real-time monitoring, callout and predictive maintenance.

Optimize compressor performance to get the most out of your assets.

Minimize fuel and power consumption through optimization and smarter automation.

Gain early warnings on potential failures to prevent costly repairs and extend asset lifespan.

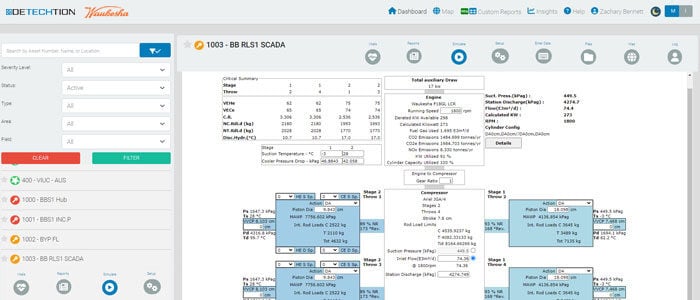

SkidIQ Adapt is a Dynamic Package Control System designed to maximize equipment utilization, prevent failures and improve uptime by leveraging a digital twin running at the edge

By combining real-time data with calculated performance metrics, it ensures compressors driven by Waukesha engines operate within the safest, most efficient range.

- Fully Integrated Package Controller: Seamless integration between compressor and ESM2 engine controllers, boosting ease of use and improving performance

- Digital Twin Running on the Edge: Control and Shutdown your asset based on its actual performance to ensure safe operations and maximum utilization.

- Dedicated Expertise and Account Management: Specialized team with unique expertise in engines and compression partnered between Waukesha Engine and Detechtion.

- Secure and Fully Remote: Reduce drive time and improve uptime by allowing operators to update setpoints and start/stop the asset remotely.

- Total Fleet Control: Identify and action the greatest opportunities in your fleet

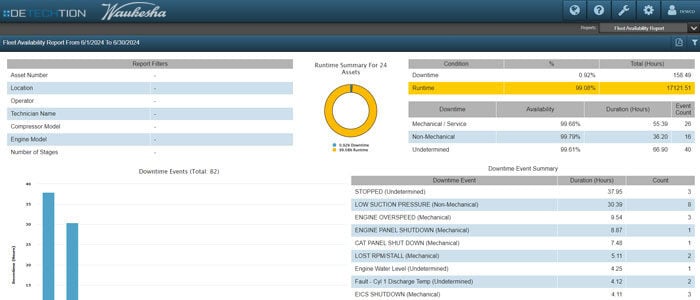

SkidIQ Manage enables you to monitor and analyze equipment for predictive maintenance programs with notifications. Ability to protect equipment while increasing production efficiency.

SkidIQ Manage Dashboard with SkidIQ Hub Device

- Improve Reliability: capture detailed downtime data and facilitate root cause analysis, illuminating the “why” behind the disruption and outlining proactive maintenance strategies.

- Surface Hidden Insights: With elevated operational responsiveness and data insights, teams can use actionable intelligence to optimize equipment performance and productivity.

SkidIQ Optimize enables you to run reports to optimize compressor operations by opening and closing valves. Ability to increase throughput and uptime.

Digital Twin and Simulator

- Maximize Throughput and Utilization: optimize the utilization of your equipment based on its operating conditions, ensuring maximum production efficiency while minimizing energy consumption

- Advanced Modeling: Our digital twin technology creates virtual replicas for each compressor and conducts precise what-if analyses for individual compressors and the entire fleet. This solution guides next-level decision-making for every operational scenario and ensures peak performance.

Boosting performance of compression skids with enhanced remote monitoring.

The innovative solution for natural gas compressor operators and gas compression leasing companies, SkidIQ’s single cloud-based platform enables operators to quickly identify and resolve issues for reduced downtime and optimized throughput

Boosting performance of compression skids with enhanced remote monitoring.

The innovative solution for natural gas compressor operators and gas compression leasing companies, SkidIQ’s single cloud-based platform enables operators to quickly identify and resolve issues for reduced downtime and optimized throughput

Detechtion Control System Resulted in $45,000/Month Benefit

By leveraging advanced PID Control Strategies, an operator was able to significantly increase uptime and utilization.

Dynamic Package Control for Compressors

Dynamic Package Control enables real-time, intelligent compressor operation.