Houston, TX |

As mentioned in the last E-Tip, “Blowby” is a term used by Detechtion Technologies to quantify inefficiencies in the compression process. Blowby is an indication of the health and efficiency of the valves and piston rings inside every cylinder. In short, it is a measure of the number of molecules of gas that are being re-circulated and recompressed within a cylinder. As more gas is re-circulated and recompressed, the temperature rise across the cylinder increases, more horsepower is required and the cylinder’s capacity to compress gas decreases.

There are several things that can result in Blowby to flag on an Enalysis report. This article focuses on the effect of damaged cylinder wear components. While the most common culprits are valves and piston rings, this also includes piston rod packing, VVCP seals, valve gaskets, etc. Essentially, any component that is meant to prevent the passage of gas under normal working conditions, could lead to Blowby when it becomes damaged.

Blowby from Damaged Valves

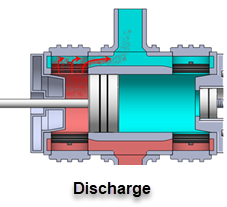

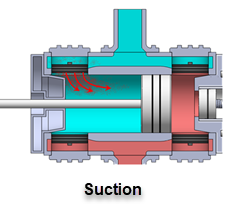

Suction and discharge valves are designed to control the flow of gas into and out of the cylinder. Gas is permitted to flow through the suction valves and into the cylinder on the suction stroke and out through the discharge valves on the discharge stroke. Therefore, any gas that can slip pass either a suction or discharge valve while that valve is supposed to be sealing is an inefficiency in the compression process.

The images below show the effects of a damaged suction valve. On the discharge stroke, partially compressed gas can slip pass the damaged crank-end suction valve. This hot gas is then brought back into the cylinder on the next suction stroke.

The recirculated gas causes excess heat to be generated and reduces the capacity of the cylinder. As a result, Blowby will increase on the Enalysis report.

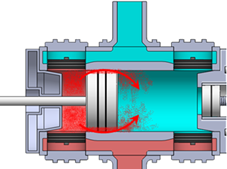

Blowby from Damaged Piston Rings

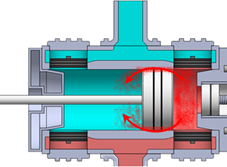

Damage to the cylinder’s piston rings can reduce the ability of the piston rings to seal and prevent the passage of gas from one side of the cylinder to the other. With this reduced ability to seal, gas can pass from the side of the cylinder where the gas is being compressed to the side bringing in new gas. This is shown in the images below.

Blowby from other Damage

Blowby can also be calculated due to damage of components other than the valves and piston rings. Damage to the following components can also cause blowby to calculate on the Enalysis report:

- Piston Rod Packing Cases

- VVCP piston sealing rings

- Cylinder liner bore scoring

- Valve gaskets

The following two image show a valve gasket that was damaged during installation. This resulted in gas leaking and blowby being calculated despite no damage to the internal valve components.

Troubleshooting Blowby for Damage

When Blowby flags on an Enalysis report, the following troubleshooting steps can be helpful:

- Run a new Enalysis report to confirm all inputs

- Record valve cap temperatures

- Compare to previous reads

- Compare comparable valve caps

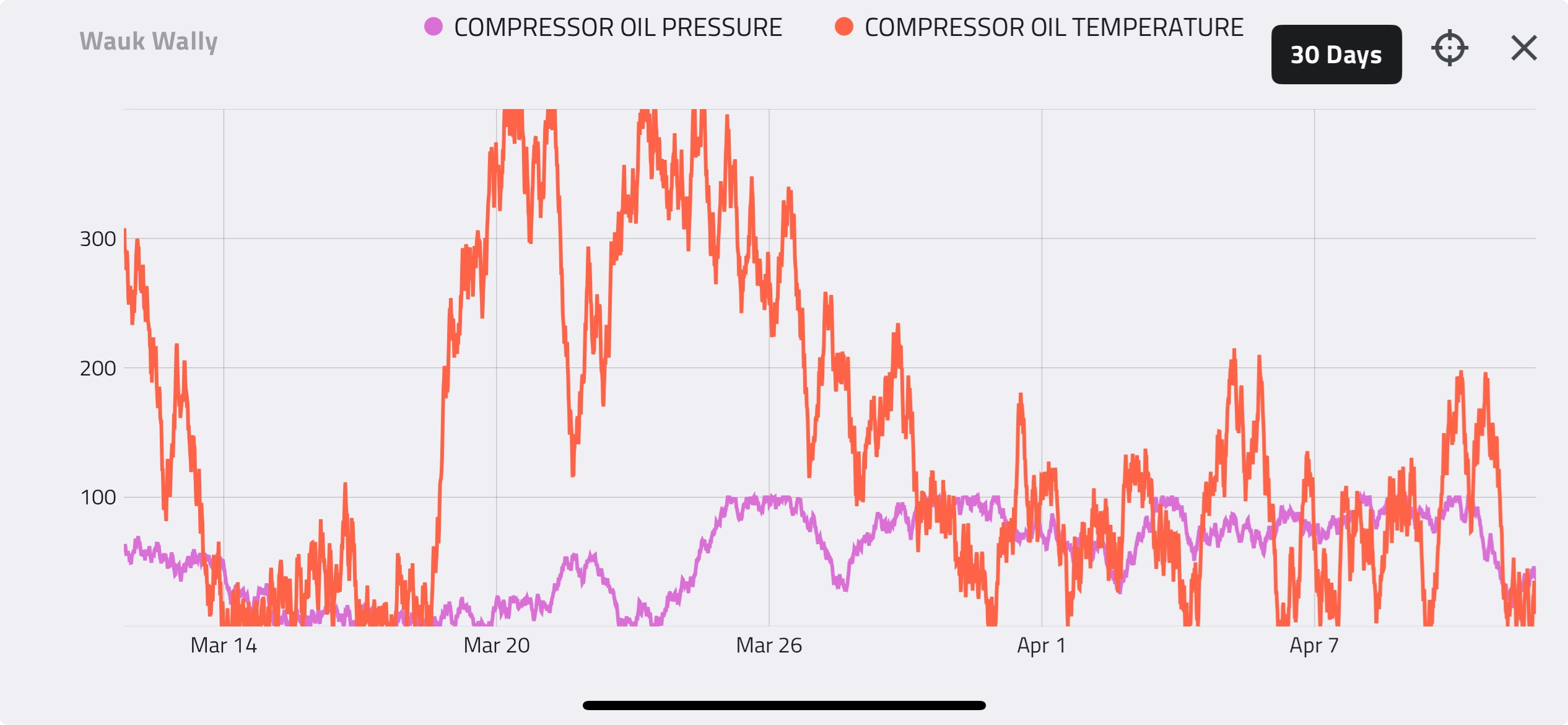

- Log into Enalysis to trend the Blowby and key cylinder process variables

Future E-Tips will discuss in greater how to troubleshoot Enalysis trends to determine causes of Blowby. Click here to read about how to troubleshoot Blowby.

Replacing Damaged Components

The following points can be valuable to consider when replacing damaged components:

- Record the serial number and location of the removed component.

- Look for any broken parts (springs, plate material, etc.) and remove to prevent this becoming foreign object /damage further down the system.

- Check cylinder liner bore for scoring or marks from foreign object damage.

- If it was a suction valve with missing springs or plates, it is likely that the discharge has been damaged and should be replaced as well?

- What events preceding the valve failure could have been contributing?

- Change in flow or pressure conditions

- HH level in the scrubber – potential liquid carryover

- High flow rate and high level in the scrubber

- Over lubrication (was the valve ‘wet’)

- Installation or part quality

- Particles from somewhere else in the system (scrubber internals, other valve parts)

Blowby Levels

Through our experience, we at Detechtion have developed guidelines that relate blowby to what can be seen within the compressor:

- Up to 10%: Light valve or piston ring wear. Difficult to see visual damage

- 10 - 15%: Obvious valve damage, broken or chipped plates and/or springs

- 16 - 30%: Severe valve and/or piston ring damage. Multiple valves potentially affected

- > 30%: Extreme damage to valve assemblies and possibly damage to cylinder lining and piston

At less than 10% blowby, it is usually going to be very difficult to identify a single valve as being damaged. However, it is possible to determine when it is cost effective to shut down a unit and examine/replace valves by taking into consideration the trends over a number of reports and the reported flow in relation to the maximum flow (from the compressor curve).

Other Probable Causes

There are many factors that can contribute to either blowby or gauge maintenance on an Enalysis report. Other than component damage, some of the most common are:

- Unaccounted pressure drops (ie. inter-stage)

- Clogged inlet suction filter (witches hats)

- Faulty temperature sensors/ IR guns

- Faulty pressure sensors

- High lube rates

- Improper valve springing

These causes will be discussed in more detail in future E-Tips.

Read Enalysis Tip 1.5 - Causes of Blowby Unaccounted Pressure Drops in Gas Compression Equipment now!