Houston, TX |

Welcome back to our "Know Pressure" webinar series, where we dive deep into the world of compressor fleet management. In the third episode, Ibee Umoh, Compressor Engineer, joined the session where we focused on a critical aspect of fleet management: optimizing compressor operations to reduce power consumption. This session explored practical steps and shared a compelling case study on achieving substantial power savings.

If you missed the live session, you can watch on-demand here:

Recap

This episode began with a brief overview of the optimization life cycle, emphasizing the importance of data collection, performance metrics, and actionable insights. Ibee introduced a fascinating case study involving a leading oil and gas producer in Canada, showcasing how Enalysis identified significant power savings on electric-driven compressor units.

Featured Case Study:

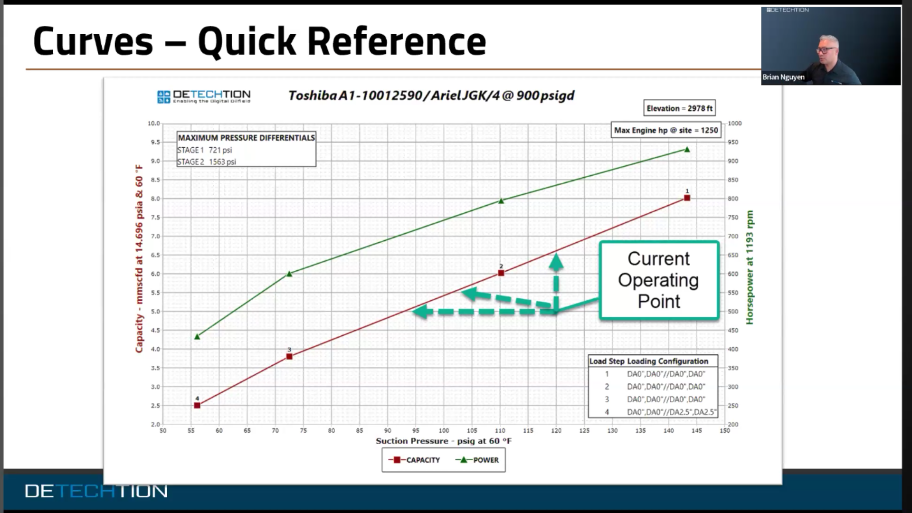

The featured case study revolved around a unique compressor setup involving a de-ethanizer between the first and second stages. The unit was identified as a candidate for optimization due to an open bypass valve, which was recycling unnecessary gas and leading to increased power consumption. Through data analysis using Enalysis, the team uncovered that the second stage was configured to handle more volume than required, resulting in inefficiencies.

To address this, the team evaluated various configurations using the Enalysis simulator and identified the optimal solution: non-acting one cylinder on the second stage. This adjustment significantly reduced the gas volume being recompressed, leading to annualized power savings of approximately $221,000 after implementation.

Additional Power Savings Opportunities:

Beyond the specific case study, the episode explored other sources of power savings within compressor operations, such as managing interstage pressure drops, identifying valve blow-by, and optimizing operations in plants with multiple units running in parallel. These insights provided attendees with a broader understanding of potential optimization areas within their fleets.

Key Insights and Takeaways:

This session underscored the value of thorough data analysis and simulation in identifying and implementing optimization opportunities. The approach demonstrated how even minor adjustments, such as reconfiguring cylinder actions or setpoints, can lead to substantial cost savings and improved operational efficiency.

REgister for Episode 4

In the next episode, we will be covering the techniques and metrics utilized within our technology to help improve equipment reliability. To register for the next episode in the series hosted on October 30 @ 12:00pm MT / 1:00pm CT, click here: