Houston, TX | March 27, 2025

Detechtion Technologies and Waukesha Engine have unveiled a game-changing innovation: SkidIQ Adapt — a newly patented solution that brings dynamic package control to reciprocating compressors. This powerful technology redefines how compressors operate, allowing them to adapt intelligently to real-time conditions for better efficiency, reliability, and performance.

Let’s break down what this means, how it works, and why it’s a big deal for the oil and gas industry.

Understanding Traditional Compressor Control Systems

Most compressor control systems today operate using a limited set of process variables within their control logic - typically suction pressure and discharge pressure. Set point limits are typically configured against these variables to ensure the compressor stays within a predefined safe operating range.

To maintain this range, the control system adjusts the Engine Speed, Bypass/Recycle control valve and Suction Control Valve.

While this setup works under stable conditions, it begins to show its limitations when gas volumes fluctuate or components start wearing - which is a common occurrence in dynamic field environments.

The Problem with Limited Set Points

Compressor operations are rarely static. Variables like upstream and downstream filter conditions can change by the hour. In a typical setup:

-

When gas volume is high (e.g., from multiple wells coming online) and the suction or discharge pressure high set point is hit, the suction control valve closes to help the compressor stay within the designated range.

-

When gas volume is low (e.g., from well decline or equipment issues) and the suction pressure low set point, engine speed is reduced and the bypass valve opens to keep the compressor within a safe operating range.

However, traditional systems only protect the unit against predefined thresholds, some of which trigger automatic shutdowns, while others don't. This creates several challenges:

-

Unplanned shutdowns when critical but avoidable thresholds are reached.

-

Undetected equipment stress (like high rod loads) that aren’t linked to shutdowns.

-

Missed opportunities to push performance when the unit is actually operating safely — especially during periods of high gas availability or low suction pressure requirements.

The bottom line? Traditional controls can lead to restricted operation, lost revenue, and increased downtime.

Enter: Dynamic Package Control

SkidIQ Adapt changes the game by introducing dynamic package control — a smarter, more responsive way to manage compressor performance.

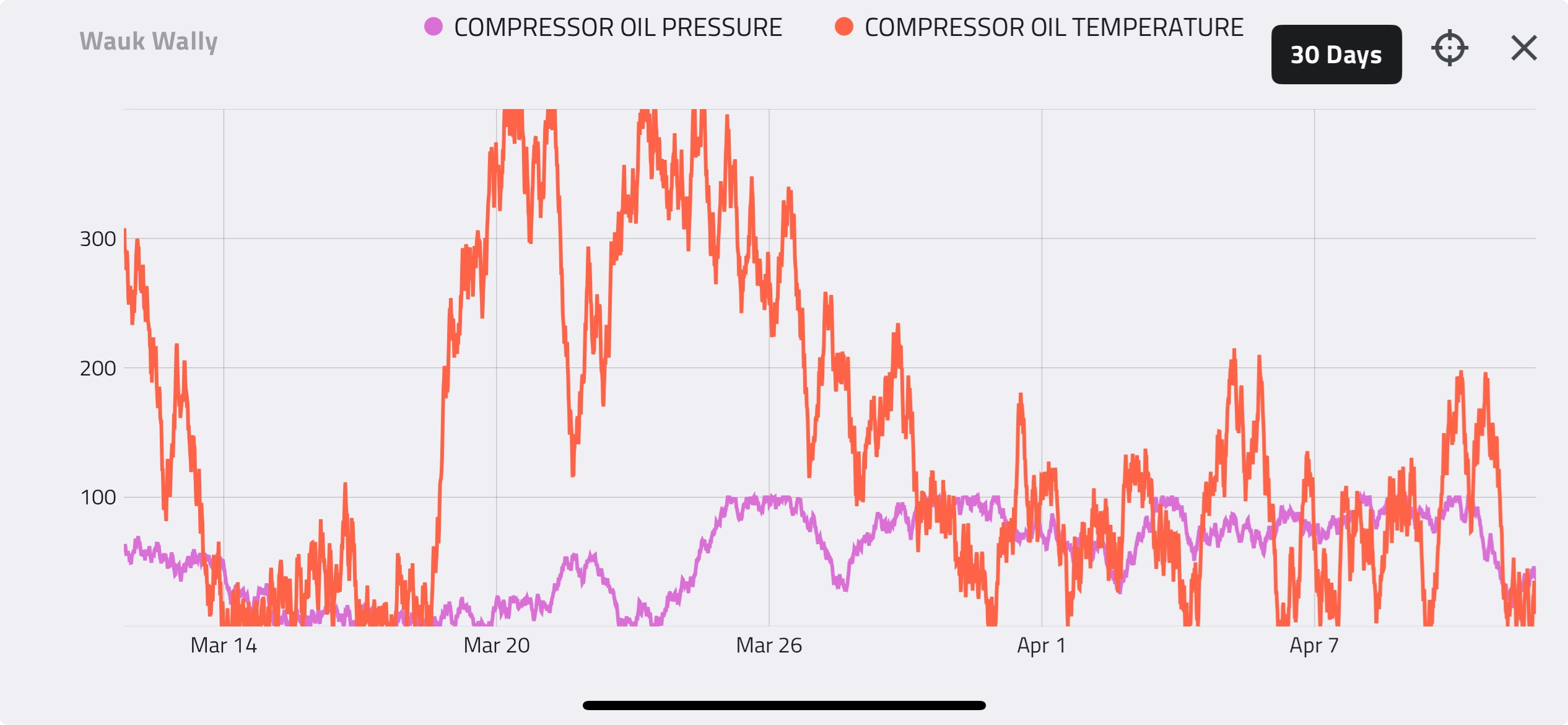

Instead of relying on just a few static variables, SkidIQ Adapt uses a wide array of real-time data — including both measured values and digital twin-calculated variables — to actively monitor the compressor’s true performance. This allows for more nuanced and accurate control.

Here’s how it helps:

-

Enhanced Protection: Real-time control of the actual performance indicators we care about (engine load, temperatures, rod loads, etc.)

-

Wider Operating Range: Confidently extend pressure ranges for more throughput and efficiency.

-

Fewer Shutdowns: Avoid unnecessary halts by adopting a control first philosophy against all critical performance variables.

-

Reduced Damage: Catch issues before they become failures, thanks to deeper insights and control against previously unmonitored performance variables.

The Results: Efficiency, Uptime, and Revenue

The benefits of dynamic package control are tangible:

-

Power savings and production optimization during periods of low gas availability.

-

Increased throughput when gas is available.

-

Improved runtime and reliability across the board.

Our analysis suggests that SkidIQ Adapt can unlock up to $150,000 per asset in combined revenue gains and cost savings.

How to Get Skid IQ Adapt

Developed collaboratively by Detechtion Technologies and Waukesha Engine, SkidIQ Adapt is the first compressor control solution purpose-built for dynamic package control.

It’s designed for flexibility and can be:

-

Installed on new compressor builds

-

Integrated into existing fleets by replacing or augmenting current control systems

This makes it easier than ever to bring modern, adaptive control to your operations — without a complete system overhaul.

Ready to Modernize Your Compressor Control?

If you're dealing with fluctuating gas volumes, reliability concerns, or want to unlock more value from your compression assets, SkidIQ Adapt offers a clear path forward.

Reach out to learn how dynamic package control can transform your operations.